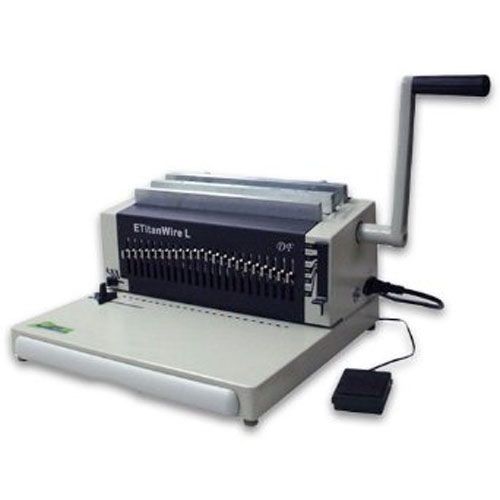

E Titan Wire L 2:1 Heavy Duty Electric Wire Binding Machine

1799.00

NewCondition

OutOfStock

We're sorry, but we no longer offer this item.

Call us at 1-800-944-4573 for personalized recommendations

or check out these similar items that may be a good fit:

E Titan Wire L 2:1 Heavy Duty Electric Wire Binding Machine

SWIPE FOR MORE IMAGES

- 0

- 1

Product Description

DFG's ETitanWire is a wire binding machine for 2:1 pitch wire binding, normally used for wire up to 1-1/4". The EtitanWire machine has the best punch tool design in its class. It can punch 1-28 sheets (20#) effortlessly and it features TurboPunch technology. This technology is developed from automotive sheet metal punching. All ETitanWire punch pins are heat-treated and precision ground to tight tolerance. ETitanWire also features a fully enclosed, high efficiency lubricated punch tool design which results in the ultra long punch tool life and super punch capacity. The ETitanWire also has the best wire closer design on the market. It features two tapered steel closing blocks with CloseAssist finish, made in a precision-controlled environment. This design assures long-lasting quality of wire closing, especially compared to competing machines' sandpaper or fabric covered sheet metal closer. Two adjustment knobs are standard, to assure even and accurate closing. This is VITAL to consistent closure of elements, no matter whose wire you use.

Product Details

- Model: ETitanWire

- Description: Heavy Duty Wire Electric Punch and Manual Binding Machine

- Structure: Solid all metal construction

- Hole Pattern: 2:1 pitch. 5/32" Rectangular holes

- Punching Capacity: 1-28 (20#) sheets per punch. Features DFG's TurboPunch

- Disengageable Pins: Full for completely clean punching with any paperr

- Anti Jam Function: Automatically prevent Jams before they happen for trouble free operation

- Wire Closing Capacity: 3/16" to 1 1/4". Two tapered steel blocks with CloseAssist finish with dual closure adjustment for long lasting accurate binding

- Punch Length: Any with full disengagement-pin, open throat design, and easy punch support

- Side Margin Control: Center holes quickly and easily

- Wire Size Selector: Built-in indicator shows suggested wire size

- Adjustable Punching Margin: Helps to improve all book's strength and design

- Power Supply: 110 V AC, 60 HZ

- Warranty: 1 Year Manufacturer Warranty

- Safety: America safety agency ETL listed

Staff Review

DFG E Titan Wire L Heavy Duty 2:1 Pitch Electric Wire Binding Machine Product Review

Overview:

- The E-TitanWire-L is an ultra heavy duty wire binding system with an electric punch. This machine is produced by Document Finishing Group (DFG for short).

- It is easily one of the best built and strongest pieces of wire binding equipment available anywhere.

- Just like the ETitanWire, the ETitanWireL is known for its durable construction, large punching capacity, heavy duty wire closer and huge number of other great features.

- These things help to set the E-TitanWire-L apart from other similar heavy duty electric wire binding punches on the market.

Features/ Strengths:

- This machine has one of the largest punch capacities available on a desktop double loop wire binding system. Document Finishing Group's Turbopunch technology allows the ETitanWireL to handle up to 28 sheets of 20lb bond paper per cycle. This large punching capacity helps to increase productivity and is designed to make binding your documents easier than ever.

- The E-TitanWireL is made almost entirely of steel and other heavy duty metals. The document table, base, wire closer, internal components and the handle are all made of metal. The heavy duty construction of this machine helps to ensure that this machine will remain strong after years of punching and binding.

- This machine is designed to punch a 2:1 pitch rectangular hole pattern. This hole pattern is compatible with standard 2:1 pitch wires and special small sized two to one pitch wire binding spines. However, it is unfortunately not compatible with other types of binding spines or supplies.

- The DFG E-Titan Wire L has one of the most durable wire closing devices available on a combination wire binding system. The closer has two heavy duty knobs that are designed to allow you to adjust the closing distance so that every spine is closed evenly. It also utilizes two precision machined blocks of steel to assist in the closing the wire spines with the utmost accuracy and without the need for sandpaper.

- The ETitanWireL also includes a continuous punching guide, 21 fully disengageable punching dies, a document sizing system for choosing the right size of spines, a foot pedal punch activator and a depth of punch margin control.

Limitations/Weaknesses:

- The ETitanWire-L is a 2:1 pitch wire binding machine. This means that it punches two holes per inch and is compatible with all of the sizes of two to one pitch wire spines. This means that this machine can be used to bind documents from 1/4" up to 1-1/4" in diameter. It cannot be used to bind documents that are larger than 1-1/4" and is not compatible with any other binding style other than twin loop wire.

- Unfortunately, the EtitanWireL only has an eleven inch punching throat. Other heavy duty electric wire binding machines such as the WireMac E have a fourteen inch punching throat for handling legal sized documents. This machine is not ideal for binding legal sized documents, A4 paper or 11" x 17" sheets.

- The Like the EtitanWire, the ETitanWire-L is missing a spine hanger. This means that operators will need to manually thread their pages onto the wire spines. If you have ever attempted to do this you know just how tedious it can be. Therefore, organizations who do purchase this machine will most likely want to come up with some type of device to assist in hanging their pages on the spines.

- Although the closing device on this machine is extremely durable, it is inconveniently located on the top of the machine. This makes it much harder to use than a closer that is on the front of a machine. Operators will need to lift their documents up and place them into the wire closer without allowing the pages to fall off the spines. This can be extremely hard to accomplish, even for seasoned binding machine operators.

Recommendation:

- The Document Finishing Group ETitanWire-L is one of the best constructed and most feature rich wire binding machines that is available anywhere.

- It includes a large punching capacity, a heavy duty wire closer and a huge number of other great features.

- However, the fact that it is missing a wire hanger and has a limited punching width puts this machine at a slight disadvantage when compared with the Akiles WireMac E.

- The WireMac-E includes most of the same great features as the ETitanWireL but also includes a wire hanger, a legal sized punching throat and a wire closer that is mounted to the front of the machine. Plus it costs about the same amount.

Questions & Answers

Thank you for your questions. The back margin which controls the amount of space between the edge of the page and punched holes, can be found on the right front of the machine. You can select the punch margin (general guideline: the thicker the book, the larger the ideal punch margin. However, you can use small punch margins for any book thickness).

Answered by MyBinding