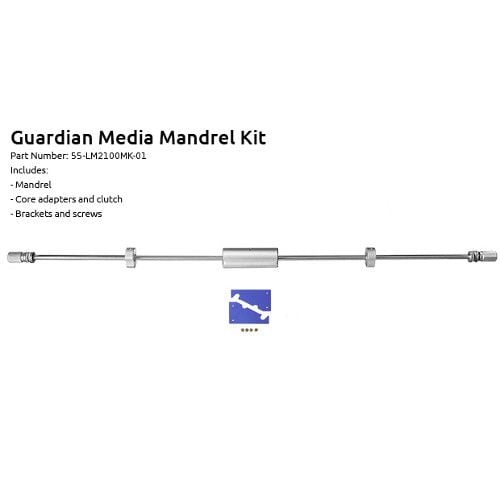

Extra Media Mandrel Kit for Guardian 82" Laminators

- 0

- 1

Product Description

Product Details

- Kit Includes: Mandrel, Core Adapters and Clutch, Brackets and Screws

- For Use With: Guardian Laminators 55-LM2100CL-01 and 55-LM2100HA-01

- Shipping Weight: 14 lbs

- Part Number: 55-LM2100MK-01

Demonstration Video

Guardian Laminator’s an affordable, easy to use solution for all of your laminating and mounting needs. You’ll have a significant impact on reducing project time while improving the durability of your media. Its all-steel construction is an obvious starting point to make a long lasting machine. The durability of the design makes for a long lifespan, protecting your investment. The high quality crowned rollers provide an even contact and pressure for a consistent fit. Drop in mandrel systems allow for easy laminate loading and adjusting, reducing downtime between jobs. Combine with the idler bar separator, webbing and fitting a wide format laminator has never been easier. The Guardian is capable of mounting and laminating media up to 65 inches wide, and with optional ReelPRO take up system can spool jobs dozens of feet long. The variable speed controls give the user complete command over the operation of the machine. With roller speeds up to 23 feet per minute, jobs that take minutes could be completed in seconds. The roller control is what makes Guardian laminators’ precision machines. Users can operate both forward and reverse smoothly and effortlessly. You can engage control hands free with the use of the foot pedal. For larger jobs, unit also has an auto control feature which runs the lamination process automatically. Some of the most important features of the Guardian are the safety controls. The safety plate ensures that the user can both web laminate and feed media while reducing the likelihood of fingers or loose clothing accidentally feeding into the machine. With both an upper position for loading laminate and mounting to board materials and a lower position for laminating to vinyl and thinner media, user has flexibility in operation while preventing accidental injury. The dual emergency stop switches are another step forward to safety control. Positioned at each side of the machine, both on the front and back sides, a user is always within reach in case the machine needs to be stopped for any reason. A simple twist of the button releases its position and allows a user to resume normal operation. Laminating process is an incredibly simple and easy to learn step by step procedure. Laminate spools from the mandrel to the idler bar, separates from the backing, and spools to the rollers and is pressed on to the media as it’s fed through. Backing separated from the laminate spools to the take up mandrel. A secondary lower mandrel system comes standard and can be used to be feed media or sacrificial material. The media table slides out for easy access for webbing and spooling lower material. This lower system also features an idler bar for even roller contact and increase functionality with an optional 4th mandrel. Mandrel and roller controls make adjusting the laminator quick and easy. The nip adjustment controls pressure for mounting and laminating thicknesses. Plus adjustable mandrel tension helps maintain a smooth, even laminate pressure that prevents wrinkles which could lead to damage jobs. The Guardian laminator is a step forward in improving production time while still maintaining quality. With its drop in mandrel system and precision roller control, users now have the functionality and easy needed in a large format laminating system. The idler bars and crowned rollers provide a smooth, clean finish and the built in safety features keep the operator safe. Take control of your workflow today with Guardian Laminators. For more information, contact your dealer or go to suply55.com.