Dynaseal 1622MKS Semi-Automatic L Bar Sealer

5571.43

NewCondition

OutOfStock

We're sorry, but we no longer offer this item.

Call us at 1-800-944-4573 for personalized recommendations

or check out these similar items that may be a good fit:

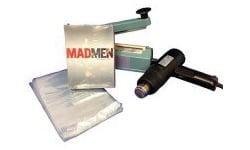

Dynaseal 1622MKS Semi-Automatic L Bar Sealer

SWIPE FOR MORE IMAGES

- 0

- 1

Product Description

Capable of sealing 10 to 12 items per minute, the Pro Pack PPG 1622 MK uses a micro knife sealing system with built-in temperature compensator to provide consistent, quality seals even in the heaviest shrink wrap production environment. PPG "L" sealers are Pro Pack's most popular shrink wrap and sealing systems and it's not surprising considering the proven performance of these feature packed machines. The PPG 1622 MK, paired with external air, can be set to run in automatic mode. In automatic mode, the operator is allowed to feed the machine while the sealing bar goes up and down as programmed (i.e. every 2 sec., 3 sec., etc.). If the operator chooses not to use the automatic feature, they can use a foot pedal to activate the sealing bar. Efficient production can be boosted even further by adding a shrink tunnel and external air to the PPG 1622 MK, allowing automatic production of sealing and discharge of product into waiting shrink tunnel at a rate of up to 15 products per minute. All of the Pro Pack "L" Sealers and shrink tunnels listed here on MyBinding, work with all of Pro Pack's Dynaclear shrink films as well as most shrink films on the market. With so many options to improve productivity and lower costs, it's no surprise Pro Pack is a leader in the worldwide packaging and shrink wrap market.

Product Details

- Manual sealing system.

- PTFE coated sealing blade.

- Permanent liquid cooling system of the sealing bar.

- Viewer of the coolant level.

- Height adjustment of the packaging plate by an external out crank.

- Mobile product-holding plate, loose from the film reel support to allow a better adjustment of the film to the pack size.

- Double hood hold-down electromagnet.

- Pack deviation device.

- Emergency button.

- Flextron control system equipped with 16-bit microprocessor for machine control and supervision and modular power section separated with solid state relays.

- Backlighted Multilanguage LCD panel.

- Possibility of storing up to 10 different working cycles.

- Seal temperature controlled by microprocessor.

- Delay adjustment in the opening of sealing arm.

- Automatic pack discharge by a motorized conveyor controlled by microprocessor.

-

Available pack formation method:

- Scrap winder device. OPTIONAL

- Double reel support. OPTIONAL

- Stainless steel packaging plate. OPTIONAL

- Foot pedal kit. OPTIONAL

- Designed and manufactured according to CE regulations.

Item Specifications

- Power Supply: 220-240 V; 1PH-N-PE 50/60Hz

- Installed Power: 2450 W

- Sealing Sizes: 22" x 17"

- Maximum Pack Height: 9"

- Production: up to 800 p/h

- Maximum Reel Size: Ø 11 3/4" x 23 1/2"

- Machine dimensions: 79" x 31" x 41 1/4" H

- Recommended Working Temperature: from +8 C° TO +40 C° - from +47 °F TO +104 °F

- Environmental Relative Humidity: Max. 70%

- Film Recommendations:

- Materials: PVC, polyolefin, polyethylene, micro perforated film

- Usable films: technical type film or films for food

- Thickness: up to 50 microns (200 gauge)