Challenge Book Trimming False Clamp Plate for Titan 200 Paper Cutter

- 0

- 1

Product Description

Pair this false clamp plate with your Challenge Machinery Titan 200 paper cutter. It is an optional accessory that is used to prevent any marking on pressure-sensitive paperwork and jobs. This plate attaches to the bottom of the clamp and is secured with wing nuts on studs that pass through the top of the clamp. It is important to note that, with the Titan 200 false clamp installed, the minimum cut is affected, changing from 1/2" to 1.75". This part is OEM / manufacturer-direct from Challenge Machinery for perfect compatibility. Sold individually.

How to Install the Titan 200 Optional False Clamp Plate

- Make sure the knife and clamp are in the up position. If they are not, turn on the power using the red and yellow main power switch, close the front guard, and press the CLEAR button. This will preset the back gauge and send the knife and clamp up.

- Turn the power off and disconnect the power cord.

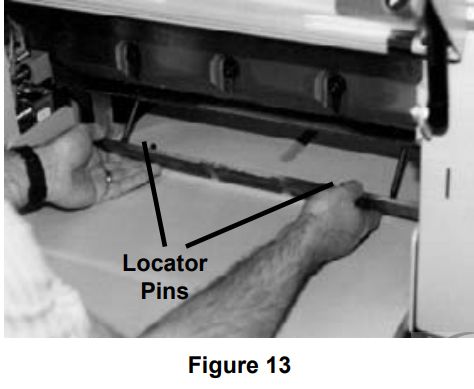

- Open the front guard (if equipped) and slide the false clamp plate under the knife and clamp (Figure 13) and slide the plate up into position with the locator pins toward the front of the machine. The locator pins insert into holes in the bottom front of the clamp.

- Hold the plate in position and secure with the wing nuts provided.

- Change the false clamp setting of the machine to ON to prevent the backgauge from crashing into the false clamp plate. This is done in the Maintenance Mode/Parameters/False Clamp screen. For more details on how to do this, see page 24.

Product Details

- Compatible with Titan 200 Paper Cutter

- OEM Manufacturer-Direct for Perfect Compatibility

- Helps Prevent Marking for Sensitive Paper Stocks

- Attaches to Bottom of Clamp with Wing Nuts

Item Specifications

- Product Type: Clamp Plate

- Compatible with: Titan 200 Paper Cutter

- Quantity: 1pk

Demonstration Video

Challenge Titan 200 Programmable Guillotines – The Challenge Machinery Company, www.challengemachinery.com. The Titan 200 line of guillotine cutters bridges the gap for many digital and in-plant locations. Solid steel and aluminum construction serves as the foundation for consistent, accurate cutting. Floating backgauge fingers and a bright red LED cut indicator. Swift backgauge positioning and table slot closure device. Monitored knife safety latch inhibits blade drifting. The Titan 200 is available with either category 4 light-beam safety curtains or tilt-shield safety cover. The backgauge programmer for the Titan 200 is extremely powerful yet intuitive for novice operators. Engineered to provide years of dependable service, the Titan 200 is suited for the demands of today’s digital or in-plant print providers. Speed, accuracy, and efficiency, the hydraulic cutter that gives you more. Over a century of providing assurance you made the right decision. Challenge Titan 200 Programmable Guillotines – The Challenge Machinery Company, www.challengemachinery.com.

We’re doing the blade change of the Titan 200. Your first step is to loosen your quarter 20 screws up above the blade. Just back those all the way out. Once those are out of your way, you loosen your first slotted screw and remove.

Your second slot and remove. This is where your knife handles will be inserted. That’s your first handle. Make sure they’re good and snug so your blade doesn’t slide. Keeps you safe. Once they’re ... Read More

We’re doing the blade change of the Titan 200. Your first step is to loosen your quarter 20 screws up above the blade. Just back those all the way out. Once those are out of your way, you loosen your first slotted screw and remove.

Your second slot and remove. This is where your knife handles will be inserted. That’s your first handle. Make sure they’re good and snug so your blade doesn’t slide. Keeps you safe. Once they’re tight, take out the rest of your blade screws. To get your blade out or remove it, loosen your handles while still holding pressure up and then bring your knife down. Pull your knife out.

Now, you got your blade out. You loosen the two bolts on your scabbard, your knife carrier, and pull the screws. Dump the blade out. Try not to touch it. These blades are extremely sharp. Load in the dull blade. Put your handles back in the new blade that you’re gonna put in the machine. Move it back. Insert the tie bolts back into the knife carrier. Make sure that your screws are tight for shipping purposes. Then install your new knife.

When installing your new blade, start low on the right hand side, lift your left end up. Be very careful not to chip the edge of your blade. Then slide it into the carrier. Make sure you’re all the way to the top. Tighten your handles. Make sure they’re not gonna slip. And then insert your blade screws. Remove the two handles. Insert the last two remaining screws. Keep them snug, not overly tight, just snug. You do not want your blade to slide in this position. Now that your blade’s in, you’re gonna want to flip your cut stick or put a new cut stick in. Here, I flipped it to a clean side. All ready to go.

Notice: The videos in this collection are an enhancement to the service manual. Please refer to the manual for additional information, specifications and procedures.

When your actual cut sheet is longer or off from your display, an accuracy adjustment is needed. I use 11 x 17-inch piece of paper to cut over the whole area of a bad gauge. Set my machine to 2 inches. The machine will beep when it's there. Make your cut. Take out my strip. I get my measurement. Right now, my ruler says I'm at 1

Notice: The videos in this collection are an enhancement to the service manual. Please refer to the manual for additional information, specifications and procedures.

When your actual cut sheet is longer or off from your display, an accuracy adjustment is needed. I use 11 x 17-inch piece of paper to cut over the whole area of a bad gauge. Set my machine to 2 inches. The machine will beep when it's there. Make your cut. Take out my strip. I get my measurement. Right now, my ruler says I'm at 1