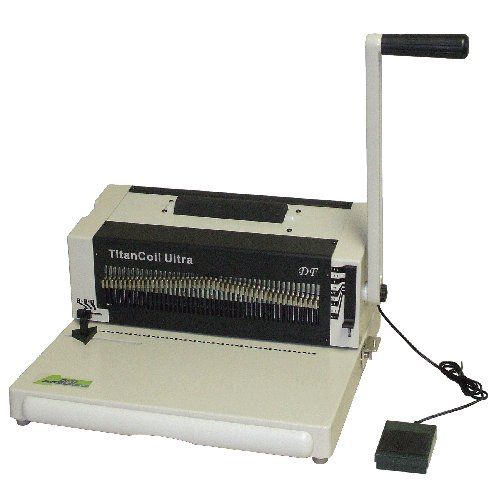

DFG TitanCoil Ultra Heavy Duty Coil Binding Machine

439.00

NewCondition

OutOfStock

We're sorry, but we no longer offer this item.

Call us at 1-800-944-4573 for personalized recommendations

or check out these similar items that may be a good fit:

DFG TitanCoil Ultra Heavy Duty Coil Binding Machine

SWIPE FOR MORE IMAGES

- 0

- 1

Product Description

The DFG TitanCoil Ultra Heavy Duty Coil Binding Machine is a professional coil binding machine with full disengagement punch pins. No other product can match this premium coil binding solution with the features your business wants at a competitive price. TitanCoil is the great choice for your commercial needs. TitanCoil punches more sheets than any other machine at its class. It also features industries first full disengagement punch pins design to guarantee the completed clean punch for any size of sheets. Not any machine at its class can do the same. TitanCoil uses high strength steel ball bearing roller mechanism, compared to the competitions’ plastic bearing.

Product Details

- Heavy Duty Machine: Single punches up to 25 sheets of paper (20 lb).

- Full Disengagement Pins: Completely clean punching for any size of sheets with 46 pull pins. This is a DFG innovation and the world’s first coil binding machine with this feature.

- Electric Coil Binding, Top Roller: Easier binding when compared to bottom mounted roller machines. Durable ball bearing roller mechanism.

- Hands Free Binding: Foot pedal controls binding actuation.

- Light Weight Design: Extensively utilized CAE, greatly reduced machine weight.

- Side Margin Control: Perfectly centered document punches.

- Coil Size Selector: Perfect coil size selection for your professional documents.

- Punch Margin Control: Optimal hole punching location for the strongest documents.

- Open Punch Throat and Continuous Punching Guide: Punching of letter, legal, or any other paper size.

- All Metal Construction: Critical functional components made of study metal.

- Large Waste Drawer: Hole punch scrap collected for a tidy workspace.

- Non-Skid Feet: Firmly holds machine to work surface.

- Free: Heavy duty coil crimper with life time warranty.

Item Specifications

- Punch Type: Manual, heavy duty, 46 pins, full disengagement, open throat

- Binding Type: Electric, top coil roller

- Punch Capacity: Up to 28 sheets of 20 lb paper

- Binding Capacity: Up to 7/8" thickness (manually bind any thickness)

- Punch Length: 11". (open throat, continous punching guide easily punch to 21" and other sizes)

- Hole Pattern: 4:1 pitch with 5/32" holes

- Power Supply: 110V AC, 60 Hz

- Weight: 30 pounds

- Manufacturer’s Warranty: One year

Staff Review

DFG TitanCoil Ultra Heavy Duty Coil Binding Machine Review

Overview:

- Most spiral coil binding machines are designed to punch sheets of standard bond papers and up to a few plastic covers at a time. However, even the strongest models have a difficult time punching through chipboard and other thick materials.

- With this in mind, DFG (Document Finishing Group) developed the TitanCoil Ultra. It is equipped with a stronger punching mechanism that makes it ideal for use in punching hard board covers.

- This opens up a whole new world of opportunities for quick printers, copy shops, print on demand operations and large corporations.

- Suddenly, the concept of producing your own coil bound hard cover documents can be a reality.

Strengths / Features:

- At first glance, the TitanCoil-Ultra looks a whole lot like the regular TitanCoil binding machine. It uses the same heavy duty metal construction and even has the same shell. In fact, if it didn’t say Ultra on the machine, it would be impossible to tell the two apart by looking at them. Both machines utilize heavy duty metal components and are extremely durable.

- Although the punching capacity of the TitanCoil Ultra is only three sheets higher than the capacity of other DFG Titan machines, it includes a larger punching throat. This larger throat is designed to allow users to insert a piece of chipboard or a custom made hard cover into the throat of the document. This is important since most coil binding machines don’t have a large enough throat to fit a piece of chipboard inside.

- This machine includes fully disengageable dies. This means that it can be set up to bind almost any size of hard cover document. It can punch any size sheet up to eleven inches in a single pass or you can use the open throat design to punch longer sheet sizes using a two step process. This means you can use the TitanCoil-Ultra to punch and bind documents as short as two inches and as long as twenty inches.

- Although the Titan-Coil Ultra is designed specifically for users who need to bind hard covered documents, it is also an excellent machine for binding regular reports, presentations and proposals with coil. It includes a coil sizing guide that helps you select the correct diameter of coil for your books. It also includes an adjustable depth of punch margin control and a foot pedal operated spiral coil inserter on the top of the machine. These features make this a great machine for binding both soft covered and hard covered documents.

Weaknesses / Limitations:

- Although this machine includes a larger punching throat and can accept thicker materials such as chip board, it can be extremely difficult to pull the handle if you load too much paper into the throat of the machine. Most individuals will have a hard time punching more than fifteen to twenty sheets of paper or two or three clear plastic covers at a time. Depending on the thickness and density of the chipboard that you need to punch, this machine may handle it easily or may require a great of force. If it is too hard to pull the handle on the machine it is a good idea to reduce the thickness of the material that you are punching so that you don’t damage your equipment.

- The TitanCoilUltra includes a foot pedal operated coil inserter that is located on the top of the machine. However, the design of this inserter and the quality of the foot pedal are less than ideal. The coil inserter uses a single roller design (as opposed to two rollers) and is only about six inches in length. This shorter length and single roller design make the inserter less effective for use with larger coils or for high speed inserting. The foot pedal is also not nearly as strong and durable as the foot pedals on other similar pieces of binding equipment.

- The chip tray or waste drawer is also fairly small on this machine considering the punching capacity that it offers. It is important to remember to empty the chip tray on a regular basis. If the chip tray becomes full it may become difficult to punch items.

Recommendation:

- Apart from a heavy duty modular binding punch which costs thousands of dollars, this machine is one of the only options available for organizations looking to punch hard covers for use with coil binding.

- It includes a larger than normal punching throat and a great set of features that make it an excellent spiral coil binding machine for handling both hard covers and soft covers.

- Although the design of the spiral coil inserter is not optimal, this machine is still an excellent choice for companies that might need to punch chipboard or thick materials.

- However, it is important to remember that if the handle is too hard to pull, you are probably punching an item that is either too dense or too thick.

This review was written by Jeff McRitchie who is the director of marketing for Mybinding.com. Jeff has written more than three hundred articles and more than two hundred reviews on Binding Machines, Binding Supplies, Report Covers, 3-Ring Binders, Index Tabs, Laminators, Laminating Supplies, Paper Shredders and Paper Handling Equipment.