MyBinding Knowledge Base

- Binding (248 Article)

- General Binding (42)

- Plastic Comb Binding (57)

- Fastback Binding (59)

- Perfect Binding (2)

- Modular Punching (8)

- Zipbind (3)

- Twin Loop Wire (13)

- Coil Binding (22)

- Thermal Binding (14)

- Strip Binding (1)

- VeloBind (4)

- Binding Covers (14)

- Proclick Binding (10)

- SureBind (4)

- Screw Post (2)

- Hole Punches (2)

- Staplers (4)

- Komtrak Insprial Binding (2)

- Paper (1)

- Rhin-O-Tuff (5)

- Binding Machines Comparison (17)

- Laminating (109 Article)

- General Laminating (26)

- Roll Lamination (16)

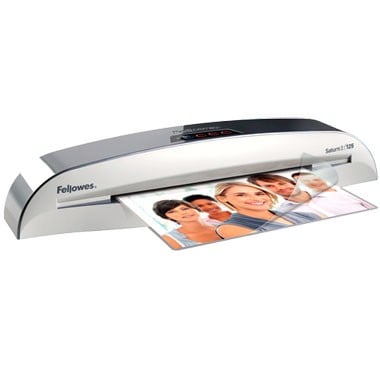

- Pouch Lamination (36)

- Pouch Board Laminator (3)

- School Laminator (3)

- Foil Laminating (3)

- Royal Sovereign Laminators (10)

- Laminators Comparison (3)

- Boards (11 Article)

- Bulletin Boards (3)

- Whiteboards (5)

- Chalkboards (1)

- Paper Shredders (44 Article)

- General Shredding (35)

- Industrial Shredders (1)

- Cross-Cut Shredders (2)

- Cardboard Shredders (1)

- Multimedia Shredders (1)

- Personal Shredders (1)

- High Security Shredders (2)

- Ring Binders (9 Article)

- Specialty Binders (2)

- Reinforced Paper (1)

- Health Care Punched Paper (1)

- Perforated Paper (2)

- View Binders (1)

- Index Tabs (9 Article)

- Index Tab Dividers (2)

- Copier Tabs (4)

- Pocket Folders (1)

- Custom Index Tabs (1)

- Pre-Printed Index Tabs (1)

- Paper Handling (37 Article)

- Paper Folders (9)

- Paper Joggers (2)

- Guillotine Cutters (4)

- Rotary Trimmer (3)

- Electronic Paper Cutters (1)

- Corner Rounders (2)

- Paper Scoring (2)

- Paper Drill (2)

- Booklet Makers (3)

- Stack Cutters (1)

- Paper Handling Equipment Comparison (5)

- ID Accessories (12 Article)

- Badge Holder (1)

- Lanyards (8)

- Badge Reels (1)

receive

$5off

*On order $25 or more.

What is a baler and should I get one?

Every business today needs a paper shredder. For those with high volumes of shredding, industrial size machines are the way to go. They can handle huge amounts of paper and other materials in a short period of time. But where does all that paper waste go? Shred bags can quickly fill and and need to be stored before they’re picked up. If you have this much detritus, you should really consider a baler to add on to your industrial shredder. Here’s why:

- Balers take shredded waste and create compact bundles ready for recycling. Use of a baler in conjunction with a shredder can reduce your scrap volume by as much as 70 percent. The storage bundles created will easily stack up as they

- They are easy to use. Large equipment can be daunting to operate. But most balers have an easy to read panel with clearly marked controls. Both audible and visual alerts let you know when a bale is finished. And bales are often ejected with a simple push of a button; some machine even offer a removable bale cart to aid you in transporting the bale to storage.

- Balers work by using hydraulics to highly compress materials. The compaction mechanism works quickly, taking as little as nine seconds to fully press down the scrap. Five to ten bales is an average hourly quotient for balers and each requires multiple presses to complete. The hydraulics are designed to be wear-free for low or no maintenance.

- The bales themselves can be held together by either straps or a bag, depending on your preference. Most have a locking flap that allows the quick addition of cardboard or other non-shredded materials.

- The mechanics are built to run fairly quiet for such a large machine. They usually have an energy saving mode that allows them to “sleep” when not in use.

- Balers must be used in conjunction with a shredder. Generally this is an industrial size shredder designed to be compatible with only a few balers. At the same time, balers are often designed to work with only a few specific shredders. The connections between the two connect in such a way to provide dust-free operation, cutting down on erosion and wear from particles. Most of the time both devices can work simultaneously, so you don’t have to stop shredding to run the baler or vice versa. This allows both machines to process massive amounts of materials as efficiently as possible.

- There are a few downsides to using a baler. First, they are very large and come with a hefty price tag. They also only work with specific shredders, so unless you already have a model that works with the baler you want, you’ll have to buy two machines. And finally, they are extremely heavy machines. Casters offer some mobility but you’ll still want to be careful when moving it around.

< Over the years, a number of customers have asked me whether they can use twin loop wire with their plastic comb binding machine. These customers often don’t want to have to buy a brand new machine but like the look and feel of twin loop wire binding. However, the answer to their question isn’t as simple as it seems. You see, they actually do make twin loop wire that is designed to work with the plastic comb binding hole pattern. With that said, if you want to use these wires you are going to need a way to close the wires. What is Spiral-O Wire? Let me explain a little bit more…There is a product that we carry called Spiral-O Wire. This wire has 19 loops and is designed to work with the hole pattern from a plastic comb binding machine. Spiral-O Wire is sometimes called Wire Combs or Ibico Wire and was originally designed for use with some of the older Ibico binding machines. A number of the older Ibico plastic comb binding machines also included a twin loop wire closer on the front of them to allow users to use both plastic combs and wire. This 19 loop wire was designed for this purpose. What Equipment is Needed? As the Ibico brand has been phased out by GBC and all of the older Ibico plastic binding machines have been replaced with new models, they no longer have the twin loop wire closer on the front of them. This presents a problem in trying to use these spiral-o wires since you can’t use the wires without a way to close them. One of the only options left is to purchase a Twin Loop wire closer. However, since twin loop wire closers are not incredibly cheap this option usually only appeals to users who have larger electric plastic comb binding machines. Otherwise, it is often advisable to simply buy a low end 3:1 pitch twin loop wire binding machine (the supplies are cheaper). This being said, if you have one of the older Ibico binding machines that has a wire closer included you are in luck. The Spiral-O binding supplies that we carry will work perfectly with your machine and you will be able to use both plastic combs and wire depending on your needs. These Spiral-O binding supplies are available in Black, Silver, White, Blue and Red and in sizes up to 1″ in diameter. If you aren’t sure what type of wire binding supplies that you need to work with your machine simply give us a call. Our trained sales representatives will be glad to help you find the correct supplies for use with your machine.(Read More)

Loading...