Foiling Troubleshooting Tips

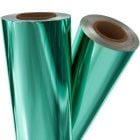

Foil fusing is a fantastic technique to transform regular printed pages into magnificent metallic prints without the need for specialized foiling equipment. Just your dry toner print, a foil roll in the color of your choice, a pouch laminator, and a shielding material called a pouch carrier are required. Here in our resource center, you can find various foil resources, such as guidelines, how-tos, FAQs, and more. You may purchase foil by clicking here.

But let's get to the main purpose of this piece, which is to troubleshoot your foil lamination. Foiling is enjoyable and simple, however there are occasionally problems that arise. You should be able to solve most, if not all, of the foiling issues you might encounter with the help of this troubleshooting guide.

Foil Not Transferring:

To solve the issue if the foil isn't transferring, there are a number of possible solutions you can try, all of which are fairly straightforward.

- Is the toner in your ink dry? Keep in mind that dry toner is the only thing that will make foil stick, so if you aren't using the suitable ink, the foil won't transfer. To determine whether it uses dry toner, check your printer and the cartridge. If not, you might be able to order your prints there, pick them up, and foil them when you get home or to the workplace. Most print and copy businesses offer these machines.

- Is the stock of your paper smooth? Remember that textured paper stocks will not transfer foil; the paper must be smooth for the foil to adhere correctly. The foil doesn't become solid in the creases because of the texture.

- Do you have uncoated paper? On coated paper stocks (often written as C1S or C2S on your box of paper), foil will not transfer well because the coating stops the ink from getting the foil to connect correctly.

- Is the laminator hot enough? Your laminator should be heated to a minimum of 300° F. However, hotter is preferable. Various foils, such as holographic and translucent foils, as well as some paper stocks, such as larger sheets, will require more heat to transfer well. If the foil laminator is already operating at maximum heat, consider reducing the speed. If your heating or cooling system isn't adjustable, try simply running it once more. You might need to use fresh foil because it can only be heated a few times before the foil becomes useless. You shouldn't peel the foil and then run it again because it might not stick after being peeled up. The impression of your design in the foil is usually visible when a transfer has been done successfully just by looking at the sheet.

Foil Transferring onto Pages Without Ink:

- Are you using a hot foil laminator? Your laminator can be too hot if you have brushed your paper and the speckles have not been erased (or too slow). To test if the speckles disappear, try reducing the temperature or speeding up the process while running a fresh sheet.

- Tool Tip: Since some speckling on the page is natural, it is a good idea to keep a paint or cleaning brush on available to lightly dust the page after foiling. This will assist in removing such flecks.

- Tracking Dots: Every sheet of color-printed paper has tiny, invisible-to-the-human-eye yellow tracking dots printed on them. These readable dots can be used to determine the printer's location, date, and purchaser. This is done so that if someone threatens someone in a printed letter, they can trace the message back to that person. You will be able to see the tracking dots if you print something in color using a loop. Although not all, the majority of printers now have tracking dots. Additionally, Google "tacky dots" and "printers." When printing in deep black, these dots have no effect on the foil fusing procedure. Therefore, if you purchase a printer that prints tracking dots and you need to print rich black, you must omit the yellow else the sheet will end up covered with tiny foiled specks after going through the foil fuser.

Foiling Tips, Tricks, and Hacks:

Techniques for foiling with thermal toner that will produce the greatest results every time.

- Foil on your Pouch Carrier: Always lay a thin scrap of paper on top of your design before foiling to stop any foil from transferring to your pouch carrier folder page. If your foil "bleeds" over the edge of your print, you should always place a scrap of paper behind it. The intention is to keep the carrier and foil from making touch. It is a good idea to have additional foil carriers on available for mistakes like this because foil can transfer onto your carrier otherwise. They are fortunately quite affordable.

- Choosing the Best Ink: Solid black ink works well for grabbing solid foils. It can give the most saturated foil finish since it is the most saturated "color." Additionally, since you won't be able to see the ink underneath, using a different color wouldn't matter. Only if you are using a transparent underlay foil, like our holographic foil, would you want to use colored ink instead (which comes in either a silver or transparent underlay). This would allow the ink color beneath the foil pattern to be seen, enhancing it. Your laminator will require more heat when using foils other than black and when utilizing more specialized foils, like translucent or holographic. Also, keep in mind that for this heat transfer foiling to function, your printer must use dry toner ink.

Ready to Get Started?

Check out the vast selection of thermal reactive toner foil we provide, which includes hundreds of choices like iridescent patterns, holographic patterns, sparkly foil, metallic and matte colors, and more. Additionally, we provide formal foil fusing machines for bigger volumes, a number of high-quality pouch laminators that have been tested and approved for foiling, as well as foil roll cutters to reduce the width of your rolls.