Tamerica TCC 2700 27" Roll Laminator

- Laminating Speed: 48" per Minute

- Max Laminate Width: 27"

- Max Film Thickness: 10 mil

- Hot or Cold: Hot

ProductDescription

Product Details

- Variable Speed.

- Spring-loaded adjustable pressure on laminating and pull rollers.

- Adjustable tension on both upper lower supply rolls to assure controlled, smooth even lamination without wrinkle or curl.

- Easy accommodation for 500 foot rolls of 1.5 mil (.0015") laminating film.

- Accepts 1.5 mil to 10 mil films

- Adjustable feed guide

- Laminating rollers made of top-grade silicon rubber.

- Heavy-duty chain & sprocket drive

- Manual with threading diagram

- Protective shield

- Silicon Heated roller for easy clearing and scratch-free lamination.

- Laminates materials up to 3/16" thick.

- Guide plate for 8.5" x 11"

- Temperature conversion feature

- Reverse function

- UL approved and CSA pending.

Item Specifications

- Power Consumption: 1600W

- Power Supply: 115V/60Hz

- Motor: DC 24V

- Max Roll Thickness: 10mil

- Max Lamination Width: 27"

- Lamination Speed: 9 Settings (18-48" per minute)

- Temperature Control: LED

- Reverse Function: Yes

- Pressure Control Function: Yes

- Roller Separation: Function Yes

- Additional Function: Machine beeps to advise that rollers are ready to run

- Shipping Length : 48

- Shipping Width: 19

- Shipping Height: 18

- Shipping (Web) Weight: 125 lbs

- Roller Material: Silicon

- Manufacturer's Warranty: 1 Year Manufacturer

Demonstration Video

Tamerica TCC 2700 27 Inch Roll Laminator Demo Video

Welcome to MyBinding video. This is a look at the Tamerica TCC 2700, a 27-inch roll laminator. It’s fast, easy to use, heavy duty, hot and cold laminating, and push button controls right here on the front. A small chart is affixed to the machine so you know what temperature and speed you need to work with with your project. The all-metal construction makes it not only heavy but heavy duty; it will last you a long time. There is a picture graph included with the machine to help you know how to install the laminating film. We have the entire video for you on that to make it easier. So refer to that for details. For now just know that this machine can handle one and a half to ten mil in laminating film thickness. Once the film is all loaded and primed, place your work table onto the grooves, put down the heat shield and set your settings. The TCC 2700 can accommodate film rolls up to 27 inches wide. So you can laminate large and many documents. Setting the sides of this tray table here allows for projects to go in consistently straight everytime and within the side of the laminating film. Adjustment on the side here allows you to move the motor faster according to what you need in thickness of your film. As you get into your project you can make adjustments as you go by widening the table for instance. Just making sure everything is on the inside of the edge of that film. Once everything is set and in place and you begin to get your rhythm, make sure you check from time to time the film on the back to make sure it’s not kinking, tangling, and has a free place to fall to. You can continue to add documents and posters of all sizes and it will continue to process one after another. It’s best to run all your projects through before making your cut from the machine. It saves time as well as laminating film. Do your trimming afterwards. That’s it, that’s the TCC 2700 by Tamerica. For more demos, reviews, and how to’s, check out MyBinding.com.

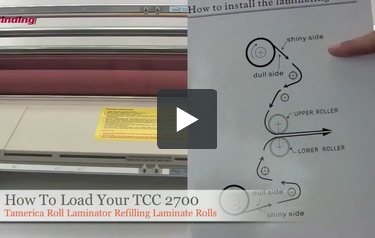

How To Load Your Tcc 2700 Roll Laminators Video

The first thing is to understand there’s a shiny side and the dull side to every roll. You have to look at the chart to find out where the shiny side lays to to make sure that your laminating rolls are facing the right direction to actually ...

Staff Review

TCC 2700 27" Roll Laminator Review

Are you looking for a roll laminator for your business or school? If so, you'll want to check out the Tamerica 2700. Here's all you need to know about this great product.

What you need to know:

-

The TC2700 has a maximum laminating width of 27 inches. It's ideal for working with large items including maps, banners, signs, and so on. You can also use it to laminate smaller documents. Everything you process can be up to 1/16" thick, so it's possible to mount some types of cardstock.

-

This device has 9 different speed settings. Depending on which on you choose, you can laminate as much as 48 inches of material in just one minute. On the slowest setting, this laminator can process 18 inches. Controlling the speed and temperature is easy because the device has an LED display.

-

This machine is compatible with film that's up to 10 mil thick. That way, your documents can be as flexible or as sturdy as you need them to be. It will even easily accommodate rolls of 1.5 mil film that are 500 feet long so you can laminate a lot of documents with just one roll.

-

The tension on both the upper and lower rolls of laminating film can be adjustable. This ensures a smooth process and flawless results.

-

Everything you laminate with this machine will look great because it has two heated rollers. The rollers are made of high-quality silicone so everything will be smooth and not marred by wrinkles and other unsightly marks.

-

If your work ever gets stuck in the machine, you won't need to worry because the reverse mode will help you remove the item.

-

This device has an integrated trimmer so removing excess laminate from your work will be a breeze. There's also an automatic shut-off feature which helps keep the motor in good shape.

-

The TC2700 is a very large machine that has dimensions of 30.5" (width) x 17.7" (depth) x 14.2" (height). You may want to think about purchasing a cart on which to store this device so you can move it out of the way if necessary. Plus, the machine weighs almost 90 pounds, so a cart with casters will definitely make transporting easier.

-

Using this device will be a safe experience because it has a protective shield to keep hands from accidentally touching the heating element.

The Tamerica TC2700 is a really terrific roll laminator that would be a welcome addition to any office, copy shop, or school. The fact that it can use film up to 10 mil thick indicates that this is a machine that can be used to laminate a wide variety of items, even those that are up to 27" wide. Thanks to the device's heated silicone rollers and the ability to adjust the tension, everything that's run through the machine will come out looking great. And the protective shield makes using the TC2700 safe to boot. If you're in the market for a roll laminator, this is one you simply must check out.

Compare to Similar Tamerica Hot Roll Laminators

| Model Name | Tamerica TCC1400i | Tamerica TSL-2700 | Tamerica TCC 27000 | Tamerica TCC 2700 | Tamerica TCC-1400F+ | Tamerica VersaLam 2700-P | Tamerica Versalam 2700-EP |

|---|---|---|---|---|---|---|---|

| Model |  |

|

|

|

|

|

|

| Lamination Thickness | 1.5 - 10 mil | 1.5 - 3 mil | 1.5 - 5 mil | 1.5 - 10 mil | 1.5 - 5 mil | 1.5 - 10 mil | 1.5 - 10 mil |

| Lamination Speed | 8.8 fpm | 5.5 fpm | 6 fpm | 4 fpm | 8.8 fpm | 4 fpm | 8.8 fpm |

| Laminating Width | 14" | 27" | 27" | 27" | 14" | 27" | 27" |

| Warm Up Time | 15 Minutes | 20 Minutes | N/A | N/A | N/A | N/A | N/A |

| Temperature Range | 194° - 248°F (90° -140°C) | 275° - 296°F (135° -146°C) | N/A | N/A | N/A | N/A | N/A |

| Speed Control | Yes | No | Yes | Yes | No | Yes | Yes |

| Temperature Control | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Roller Adjustment | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Mounting Capability | up to 3/16" | Up to 1/4" | Up to 1/4" | Up to 3/16" | Up to 3/16" | Up to 3/16" | Up to 1/4" |

| Reverse Function | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Core Size | 1" | 1" | 1" | 1" | 1" | 1" and 3" | 1" and 3" |

| Dimensions | 34" x 24" x 18" | 34" x 13" x 14" | 48" x 19" x 18" | 48" x 19" x 18" | 34" x 19" x 18" | 27" x 14" x 24" | 51" x 27" x 24" |

| Power Voltage | 110 Volts 15amp | 110 Volts 15amp | 115V/60Hz/1600W | 115V/60Hz/1600W | 115V/60Hz/1600W | 115V/60Hz/1600W | 115V/60Hz/1600W |

| Warranty | Limited 1 Manufacturer's Warranty | Limited 1 Manufacturer's Warranty | 1 Year Manufacturer's Warranty | 1 Year Manufacturer's Warranty | 1 Year Manufacturer's Warranty | 1 Year Manufacturer's Warranty | 1 Year Manufacturer's Warranty |