MyBinding Knowledge Base

- Binding (248 Article)

- General Binding (42)

- Plastic Comb Binding (57)

- Fastback Binding (59)

- Perfect Binding (2)

- Modular Punching (8)

- Zipbind (3)

- Twin Loop Wire (13)

- Coil Binding (22)

- Thermal Binding (14)

- Strip Binding (1)

- VeloBind (4)

- Binding Covers (14)

- Proclick Binding (10)

- SureBind (4)

- Screw Post (2)

- Hole Punches (2)

- Staplers (4)

- Komtrak Insprial Binding (2)

- Paper (1)

- Rhin-O-Tuff (5)

- Binding Machines Comparison (17)

- Laminating (109 Article)

- General Laminating (26)

- Roll Lamination (16)

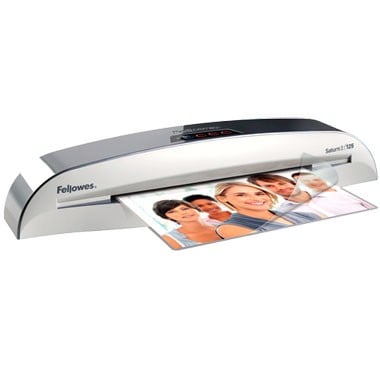

- Pouch Lamination (36)

- Pouch Board Laminator (3)

- School Laminator (3)

- Foil Laminating (3)

- Royal Sovereign Laminators (10)

- Laminators Comparison (3)

- Boards (11 Article)

- Bulletin Boards (3)

- Whiteboards (5)

- Chalkboards (1)

- Paper Shredders (44 Article)

- General Shredding (35)

- Industrial Shredders (1)

- Cross-Cut Shredders (2)

- Cardboard Shredders (1)

- Multimedia Shredders (1)

- Personal Shredders (1)

- High Security Shredders (2)

- Ring Binders (9 Article)

- Specialty Binders (2)

- Reinforced Paper (1)

- Health Care Punched Paper (1)

- Perforated Paper (2)

- View Binders (1)

- Index Tabs (9 Article)

- Index Tab Dividers (2)

- Copier Tabs (4)

- Pocket Folders (1)

- Custom Index Tabs (1)

- Pre-Printed Index Tabs (1)

- Paper Handling (37 Article)

- Paper Folders (9)

- Paper Joggers (2)

- Guillotine Cutters (4)

- Rotary Trimmer (3)

- Electronic Paper Cutters (1)

- Corner Rounders (2)

- Paper Scoring (2)

- Paper Drill (2)

- Booklet Makers (3)

- Stack Cutters (1)

- Paper Handling Equipment Comparison (5)

- ID Accessories (12 Article)

- Badge Holder (1)

- Lanyards (8)

- Badge Reels (1)

receive

$5off

*On order $25 or more.

How can I customize hardcovers with my Fastback binding system?

Headbands are narrow strips of cloth fastened between the book block and the spine at the top and bottom of a book. Although they were once an integral part of the binding process, most headbands today are used as attractive decorative touches. Fastback Headbands come in a variety of solid and checkered color combinations.

Installing Headbands on your document is actually quite easy. However, you will need to add them before you insert your book block into your hard cover case. You then peel the release paper backward exposing the adhesive backing and align the edge of the headband with the edge of your book block. You then can trim the headband strip to the same width as the book block. Headband strips come in packs of 25 and are six inches long each. This means you can use a single Fastback headband to bind multiple books.

Fastback FoilFast Title Sheets:

Using Powis Parker’s Foilfast printer, you can title and decorate your covers with up to seven colors of foil. Foilfast Title Sheets are made of the same materials as the Fastback Hardcovers so you are ensured of a perfect match. They may also be used to create spine titles for you books. Foilfast Title Sheets are slightly smaller than their corresponding covers. For instance, the FTS for the letter-size Fastback Hardcover is 8-1/8″ rather than 8-1/2″ wide. Artwork that you want to center on the book covers should have its center 4″ from the left edge of the sheet.

Using FoilFast title sheets is actually quite easy. First, you Insert the Foilfast Title Sheet (FTS) into the Foilfast printer so that the narrow release paper is on the left side and facing away from you. Compose your design with any software.

When you are finished choose File > Print. Click on the “Properties” button in the Print window to open the Properties dialog box. Choose the “Upside Down” option. Put your cover in the Fastback Hardcover Guide with the exterior of the hard cover face up. Make sure that the front cover is pushed all the way into the corners of the Guide recess, beneath the green stops. Lock the cover in place by depressing the lever to the right. Remove the narrow release paper from the FTS. Align the top and right sides of the FTS against the edge of the green paper stops. Then, press the exposed adhesive area onto the cover. Gently lift the right end of the FTS and remove the large release paper. Lay down the FTS onto your cover. Smooth down the FTS to complete your custom printed cover.

Traditional Customization Options:

If you are looking for a cover that has more customization or are looking to bind a large number of documents with the same size of covers, it is possible to use other customization techniques. You can order hard covers with custom hot foil stamping, silk screening or offset printing. You can even order covers with full bleed offset printing wrapped around the entire case. These options usually require larger quantities and proof approvals before proceeding. However, they also provide the most options for customization and brand enhancement.

< Over the years, a number of customers have asked me whether they can use twin loop wire with their plastic comb binding machine. These customers often don’t want to have to buy a brand new machine but like the look and feel of twin loop wire binding. However, the answer to their question isn’t as simple as it seems. You see, they actually do make twin loop wire that is designed to work with the plastic comb binding hole pattern. With that said, if you want to use these wires you are going to need a way to close the wires. What is Spiral-O Wire? Let me explain a little bit more…There is a product that we carry called Spiral-O Wire. This wire has 19 loops and is designed to work with the hole pattern from a plastic comb binding machine. Spiral-O Wire is sometimes called Wire Combs or Ibico Wire and was originally designed for use with some of the older Ibico binding machines. A number of the older Ibico plastic comb binding machines also included a twin loop wire closer on the front of them to allow users to use both plastic combs and wire. This 19 loop wire was designed for this purpose. What Equipment is Needed? As the Ibico brand has been phased out by GBC and all of the older Ibico plastic binding machines have been replaced with new models, they no longer have the twin loop wire closer on the front of them. This presents a problem in trying to use these spiral-o wires since you can’t use the wires without a way to close them. One of the only options left is to purchase a Twin Loop wire closer. However, since twin loop wire closers are not incredibly cheap this option usually only appeals to users who have larger electric plastic comb binding machines. Otherwise, it is often advisable to simply buy a low end 3:1 pitch twin loop wire binding machine (the supplies are cheaper). This being said, if you have one of the older Ibico binding machines that has a wire closer included you are in luck. The Spiral-O binding supplies that we carry will work perfectly with your machine and you will be able to use both plastic combs and wire depending on your needs. These Spiral-O binding supplies are available in Black, Silver, White, Blue and Red and in sizes up to 1″ in diameter. If you aren’t sure what type of wire binding supplies that you need to work with your machine simply give us a call. Our trained sales representatives will be glad to help you find the correct supplies for use with your machine.(Read More)

Loading...