MyBinding Knowledge Base

- Binding (248 Article)

- General Binding (42)

- Plastic Comb Binding (57)

- Fastback Binding (59)

- Perfect Binding (2)

- Modular Punching (8)

- Zipbind (3)

- Twin Loop Wire (13)

- Coil Binding (22)

- Thermal Binding (14)

- Strip Binding (1)

- VeloBind (4)

- Binding Covers (14)

- Proclick Binding (10)

- SureBind (4)

- Screw Post (2)

- Hole Punches (2)

- Staplers (4)

- Komtrak Insprial Binding (2)

- Paper (1)

- Rhin-O-Tuff (5)

- Binding Machines Comparison (17)

- Laminating (109 Article)

- General Laminating (26)

- Roll Lamination (16)

- Pouch Lamination (36)

- Pouch Board Laminator (3)

- School Laminator (3)

- Foil Laminating (3)

- Royal Sovereign Laminators (10)

- Laminators Comparison (3)

- Boards (11 Article)

- Bulletin Boards (3)

- Whiteboards (5)

- Chalkboards (1)

- Paper Shredders (44 Article)

- General Shredding (35)

- Industrial Shredders (1)

- Cross-Cut Shredders (2)

- Cardboard Shredders (1)

- Multimedia Shredders (1)

- Personal Shredders (1)

- High Security Shredders (2)

- Ring Binders (9 Article)

- Specialty Binders (2)

- Reinforced Paper (1)

- Health Care Punched Paper (1)

- Perforated Paper (2)

- View Binders (1)

- Index Tabs (9 Article)

- Index Tab Dividers (2)

- Copier Tabs (4)

- Pocket Folders (1)

- Custom Index Tabs (1)

- Pre-Printed Index Tabs (1)

- Paper Handling (37 Article)

- Paper Folders (9)

- Paper Joggers (2)

- Guillotine Cutters (4)

- Rotary Trimmer (3)

- Electronic Paper Cutters (1)

- Corner Rounders (2)

- Paper Scoring (2)

- Paper Drill (2)

- Booklet Makers (3)

- Stack Cutters (1)

- Paper Handling Equipment Comparison (5)

- ID Accessories (12 Article)

- Badge Holder (1)

- Lanyards (8)

- Badge Reels (1)

receive

$5off

*On order $25 or more.

Can I use my laminator to make ID badges?

There are a surprising number of things to consider when you are making ID badges for your team members. Here are a few tips to get you started.

Gather Material.

First you have to decide what information you want to include on your ID badges. Name and photo are no-brainers, of course, but you might also want to include the title of the badge holder, along with his or her department, and what their security clearance is, if need be.

Ideally, there should be some way for your security team and for other employees to tell from somewhat of a distance whether a badge is still up to date and valid. Some ideas that may help enable this would be creating badges with a different color background for each year, or for visitors and current employees. There have been some advancements in this area, including badges that fade to white within a specified time period, such as 48 hours. Take a look online at what your options may be in this regard.

Choose a Badge Type.

There really are a number of choices to be made here with regards to functionality and your budget, so don’t be in a hurry when you are doing your research. There’s anything from the simplest laminated paper badge with an inexpensive plastic clip to PVC cards with magnetic strips on the end of imprinted and customized breakaway lanyards.

One other factor to consider is what size of badge you will need. You’ll want to make sure that all the information you desire can fit onto the card, but you still want it to be readable. This might take some thought and editing, and if you have a design team, you might want to get them on the case.

Get Them Printed

There are a couple different ways to go about this, of course. There are plenty of websites out there that can do a reasonable job for you, with templates and lots of color options and the like. VistaPrint, My Simon and Bizrate are some places to start. Your local print shop should be able to give you some guidance as well.

If you are more of a do-it-yourselfer, you can use programs such as MS Word, Indesign, or Photoshop to either create and do your own artwork, or use their templates. In Word, you can go to the Labels section and there will be a template there for you to use. It would be a good idea to save and keep the templates handy so you can quickly bring them up and update them whenever necessary. When it comes to printing and laminating your ID badges, there are a few different options. You can upload that artwork to the aforementioned sites, for instance, send the job to your local printer, or print and laminate them yourself in your office.

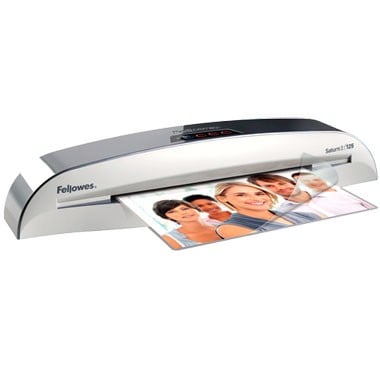

There are a lot of pouch laminating machines on the market with lots of different capabilities, and they are all fairly easy to use and inexpensive. If you are going to be in the position of creating a large number of badges on a regular basis, or need the ability to make ID badges at a moment’s notice, you should look into purchasing your own pouch laminating machine.

< Over the years, a number of customers have asked me whether they can use twin loop wire with their plastic comb binding machine. These customers often don’t want to have to buy a brand new machine but like the look and feel of twin loop wire binding. However, the answer to their question isn’t as simple as it seems. You see, they actually do make twin loop wire that is designed to work with the plastic comb binding hole pattern. With that said, if you want to use these wires you are going to need a way to close the wires. What is Spiral-O Wire? Let me explain a little bit more…There is a product that we carry called Spiral-O Wire. This wire has 19 loops and is designed to work with the hole pattern from a plastic comb binding machine. Spiral-O Wire is sometimes called Wire Combs or Ibico Wire and was originally designed for use with some of the older Ibico binding machines. A number of the older Ibico plastic comb binding machines also included a twin loop wire closer on the front of them to allow users to use both plastic combs and wire. This 19 loop wire was designed for this purpose. What Equipment is Needed? As the Ibico brand has been phased out by GBC and all of the older Ibico plastic binding machines have been replaced with new models, they no longer have the twin loop wire closer on the front of them. This presents a problem in trying to use these spiral-o wires since you can’t use the wires without a way to close them. One of the only options left is to purchase a Twin Loop wire closer. However, since twin loop wire closers are not incredibly cheap this option usually only appeals to users who have larger electric plastic comb binding machines. Otherwise, it is often advisable to simply buy a low end 3:1 pitch twin loop wire binding machine (the supplies are cheaper). This being said, if you have one of the older Ibico binding machines that has a wire closer included you are in luck. The Spiral-O binding supplies that we carry will work perfectly with your machine and you will be able to use both plastic combs and wire depending on your needs. These Spiral-O binding supplies are available in Black, Silver, White, Blue and Red and in sizes up to 1″ in diameter. If you aren’t sure what type of wire binding supplies that you need to work with your machine simply give us a call. Our trained sales representatives will be glad to help you find the correct supplies for use with your machine.(Read More)

Loading...