We're sorry, but we no longer offer this item.

Call us at 1-800-944-4573 for personalized recommendations

or check out these similar items that may be a good fit:

Thermal Binding Glue Strips for Create Your Own Covers - 40pk

- Width: 1 inch

- length: 11 inches

- Thickness: 1 mm

- Product Number: BIADSTRIP11

ProductDescription

Product Details

- Width: 1 inch

- length: 11 inches

- Thickness: 1 mm

- Quantity: 40pk

- Product Number: BIADSTRIP11

Demonstration Video

How to Create Your Own Cover

For our covers, we’ll be using a custom cut sheet—for the length, every measurement after 17 inches will be the thickness of your book, to which you can measure your stack before you cut or purchase the covers.

The first thing we are going to do is crease our cover.

And I do not mean, fold it be hand. Here is a closeup of a hand folded crease—notice how it looks cracked. Now compare it to the creases made by a creaser, and you’ll see how much better this cover loo ...

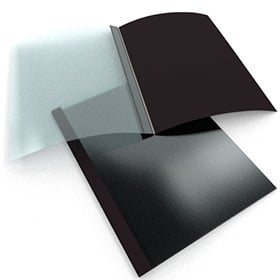

The materials we’ll be using are: a wrap around cover sheet, a glue strip, and your stack of pages

For our covers, we’ll be using a custom cut sheet—for the length, every measurement after 17 inches will be the thickness of your book, to which you can measure your stack before you cut or purchase the covers.

The first thing we are going to do is crease our cover.

And I do not mean, fold it be hand. Here is a closeup of a hand folded crease—notice how it looks cracked. Now compare it to the creases made by a creaser, and you’ll see how much better this cover looks.

Okay, back to creasing—we’re going to make four creases for the best quality. I’m using the Fastbind C400 for this demo.

The C400 has double edged guides that I already measured out to 8.5 inches on both sides. You want to make a crease at both edges, and you’ll see why.

So here you can see the final result of 4 creased lines, two on each side from each guide on the machine. Two creases works as well if you want a quicker process.

Now we’re going to fold the inner two lines to make the shape of our book.

Next take a glue strip and cut it to fit in the spine of our project we just folded together.

Place the glue strip into the center of your cover. We don’t want it going over the edges, so trim off the ends so that there is about a centimeter, or a little less, of space between the ends.

With the glue still cradled in the center, pick up the cover and insert your pages, already printed, over the glue. Then jog your pages in place, nice and even.

Now insert your project into your thermal binding machine—here you can see I am using the Pro-Bind 1000.

When it’s complete, remove your project, tamp it down again to make sure all the pages are in the glue and let it cool.

In my first book, I did not cut my glue thick enough to cover the full width of the spine in all areas—in result you can see parts of pages are still exposed where they should not be. So make sure your glue strip fits well.

It’s kind of funny, now on my second book I did not leave enough space between the glue and the edge of the covers, so the glue came out then ends, onto my machine, to which I then had to clean—which is no fun.

So with a little experimentation, now you can find out how to best create a soft cover book for each of your own projects. It’s highly recommend to run some test first to get the process down before you bind your final projects.