We're sorry, but we no longer offer this item.

Call us at 1-800-944-4573 for personalized recommendations

or check out these similar items that may be a good fit:

Coverbind CPB1 Table-Top Perfect Binding Machine and Accessories

- Bind up to 360 books per hour

- Bind books up to 2.25” thick

- Made for binding book blocks up to 12.5"H x 8.7"W

- Ideal for in-plant and on-demand print shops

ProductDescription

Make professional perfect bound books with perfect binding machines. This tabletop machine by Coverbind is conveniently compact, very fast, and affordable for use in nearly any in-house print shops. It offers a cost-effective and efficient solution for making softback bound books.

Use on any work surface you already have, or pair with the optional stand designed to lift the CPB1 to optimum working height, without taking up unnecessary floor space. The LCD display and simple controls make for quick setup and easy operation. You can set the machine for your specific job specifications and begin binding together your soft-cover books, novels, manuals, and much more; on-demand perfect binding has never been easier.

Automate the binding of soft cover books with the Coverbind CPB1 perfect binder system. It can process up to 360 books per hour and allows the operator complete control over the machine functions, such as the spin positions, angled options, cover stock, height of the book, and more. It offers automatic/pneumatic clamping, specialized nipping, and essential glue coverage for a secure bind.

Product Details

- Fast Binding. Bind up to 360 books per hour, depending on the book specifications and operator capabilities.

- Efficient Controls. A simple control panel lets you customize the machine to your specific job quickly.

- Automated Clamping. A pneumatic powered clamping mechanisms automatically adjusts to your book block thickness up to 2-1/4”.

- Optimum Glue Penetration. Roughing blade includes a serrated edge with 4 notching pins for maximum glue penetration and finished book strength.

- Specialized Nipping. Set the nipper to produce an exceptionally square-backed book with an adjustable height and dwell time up to 8 seconds.

- Stronger Bind. Side gluing on the front and rear of the book block makes for exceptional finishing.

- Saturated Glue Coverage. Twin gluing rollers saturate the spine with adhesive while a separate adjustable metering roller smooths the glue to the optimum thickness.

Item Specifications

- Maximum Speed:Up to 360 books/hour

- Max Book Thickness: 2.25" / 57mm

- Max Cover Size: 13.4" x 30.75" / 34 x 78 cm

- Maximum Spine Length: 12.5" / 32cm

- Book Block Size: 12.6" x 8.7"

- Display: LCD Screen

- Clamp: Automatic/Pneumatic

- Roughing Blade: Roughing Blade and 4 Notching Pins

- Rollers: 2 Glue, 1 Metering

- Air Compressor: Air Compressor is Included

- Castors: Included on Stand (Optional Stand is Sold Separately)

- Machine Dimensions: 17” H x 32” W x 54-1/2” L (45” x 32” x 54-1/2” for Optional Stand)

- Shipping Dimensions: 37” H x 26” W x 73” L

- Machine Weight: 525 lbs. (142 lbs. for Optional Stand)

- Shipping Weight: 585 lbs.

- Electrical: 220W 1 Phase, 10 Amp. 2.2Kw

- Compatible Supplies: Coverbind Standard Perfect Bind Adhesive

Coverbind Premium Perfect Bind Adhesive - Compatible Accessories: Cabinet for Coverbind CPB1 Perfect Binder with Storage

Demonstration Video

Coverbind CPB1 Perfect Binding Machine Video

This fully automated perfect binding system fits conveniently on a tabletop, offering automatic pneumatic clamping, nipping, and exacting glue coverage for a secure bind.

This CPB1 perfect binder system lets you bind softback books easily with a simple to use control panel that lets you customize the machine to your specific job quickly.

Start binding books on-demand, the pneumatic powered clamping mechanism ...

This fully automated perfect binding system fits conveniently on a tabletop, offering automatic pneumatic clamping, nipping, and exacting glue coverage for a secure bind.

This CPB1 perfect binder system lets you bind softback books easily with a simple to use control panel that lets you customize the machine to your specific job quickly.

Start binding books on-demand, the pneumatic powered clamping mechanisms automatically adjust to your book block thickness from two sheets of paper up to 2-1/4” thick.

The CPB1 is a production powerhouse able to bind up to 360 books per hour, depending on the book specifications and operator capabilities.

In addition to doing the binding, the CPB1 can also be used to make pads. Change-over between each binding and padding is completed with just the push of a button, so there is no downtime when job requirements change.

The CPB1 has a unique roughing blade that includes a serrated edge and notching pins allowing for binding strength with maximum glue penetration.

The dual glue application rollers make sure the glue is applied to all surfaces of the spine and the metering roller smooths out the glue to the desired thickness. There is a side glue wire attached to the glue application rollers that applies a bead of adhesive on one side of the book block.

Additionally, the unique action of the nipping table pushes glue to the front side of the book block providing strong adhesion of the cover to the book block.

Both the clamp and nipping table are pneumatic and operate with the compressor that is included with the system. The nipping table has an adjustable height and dwell time of up to 3 seconds. The nipper adjustment knob allows the operator to increase or decrease the travel of the nipper to produce an exceptionally square-backed book.

There are 3 important sensors on the machine. 1. The book clamp sensor will prevent the book clamp from closing without a book block in the machine.

2. The cover sensor will prevent to book block from moving across the gluing section and into the nipping table unless a cover is in place

3. The safety touch sensor on the top of the clamp, will automatically open the clamp if a hand is on the book clamp.

The exit tray provides a staging area for cover stock and an area to stack books as they come out of the machine. An optional stand with castors is available, making it easy to move around the shop where needed or out of the way when not in use.

Accomplish swift, simple, and automated binding for your perfect bound books with the Coverbind CPB1. An ideal perfect binding solution for in-plant and on-demand print shops and binderies.

Resources

Staff Review

Coverbind CBP1 Expert Review

WHAT I LIKE:

With the Coverbind CBP1 perfect binding machine, you will have complete control over the bookbinding process so you can create perfectly perfect-bound books in a flash. The LCD control panel has straightforward controls that make it easy to change bookbinding settings like the cover stock, angled options, the height of the book thickness, spin positions, and more. When you load up your pages on the block, the automated clamping system will then auto-adjust to fit the size, and you know you're getting tight, clean binds every time.

Your paperback-bound books will come out with a perfectly flat spine, allowing you to easily display book titles and author names. With this perfect binding method, you’ll see how versatile it is, and how you can use it for a wide range of soft cover books. You’ll find that this gluing method is not only productive but cost-efficient as well.

THINGS TO CONSIDER:

If you have limited volume or space, you might not need the Coverbind CBP1. It's easy to move if you need to rearrange your workspace or grab the optional stand to place this table-top binder on if you don't already have a table set aside for it. If your print company demands up to 360 paperback books per hour, I recommend adding this to your shop.

I RECOMMEND THIS FOR:

For a range of binding requirements, from basic to complicated, the Coverbind CBP1 is a great option. I suggest this excellent binder for large businesses that need to fill thousands of books per day at print companies that routinely fulfill on-demand orders for novels. This excellent binder can make your binding procedure quick and simple while also being priced fairly with different machines on the market.

If you have the space and and are looking for a machine with a dedicated air compressor, side gluer tank, and dust bin collector, check out the CBP1’s “older brother,” the Coverbind CPB2SG. The Coverbind CPB2SG is for those who want to skip manual cleaning thanks to the dust collector, an additional safety guard, and who want a more professional bind thanks to the dedicated glue tank.

THE BOTTOM LINE:

Perfect binding machines is a wonderful choice for you if you're an on-demand print business or facility that has to bind hundreds of books each hour. Your books are bound neatly and quickly thanks to its effective controls, saturating glue coverage, and automated clamping. Using straightforward controls and an LCD allows for quick setup and operation. Start immediately binding high-quality paperback books, novels, manuals, and more after setting up the machine per your precise task needs. Up your production output and binding efficiency with the tabletop powerhouse Coverbind CPB1.

Our Binding101 staff reviews are written by various team members across the company, bringing together decades of experience in the industry and at our company. With unique experience and insights into customer service and manufacturing, our goal with these reviews is to help you make an educated buying decision. If you're seeking more help choosing the best item for your unique needs, please don't hesitate to contact us at (866)537-2244.

Features and Benefits

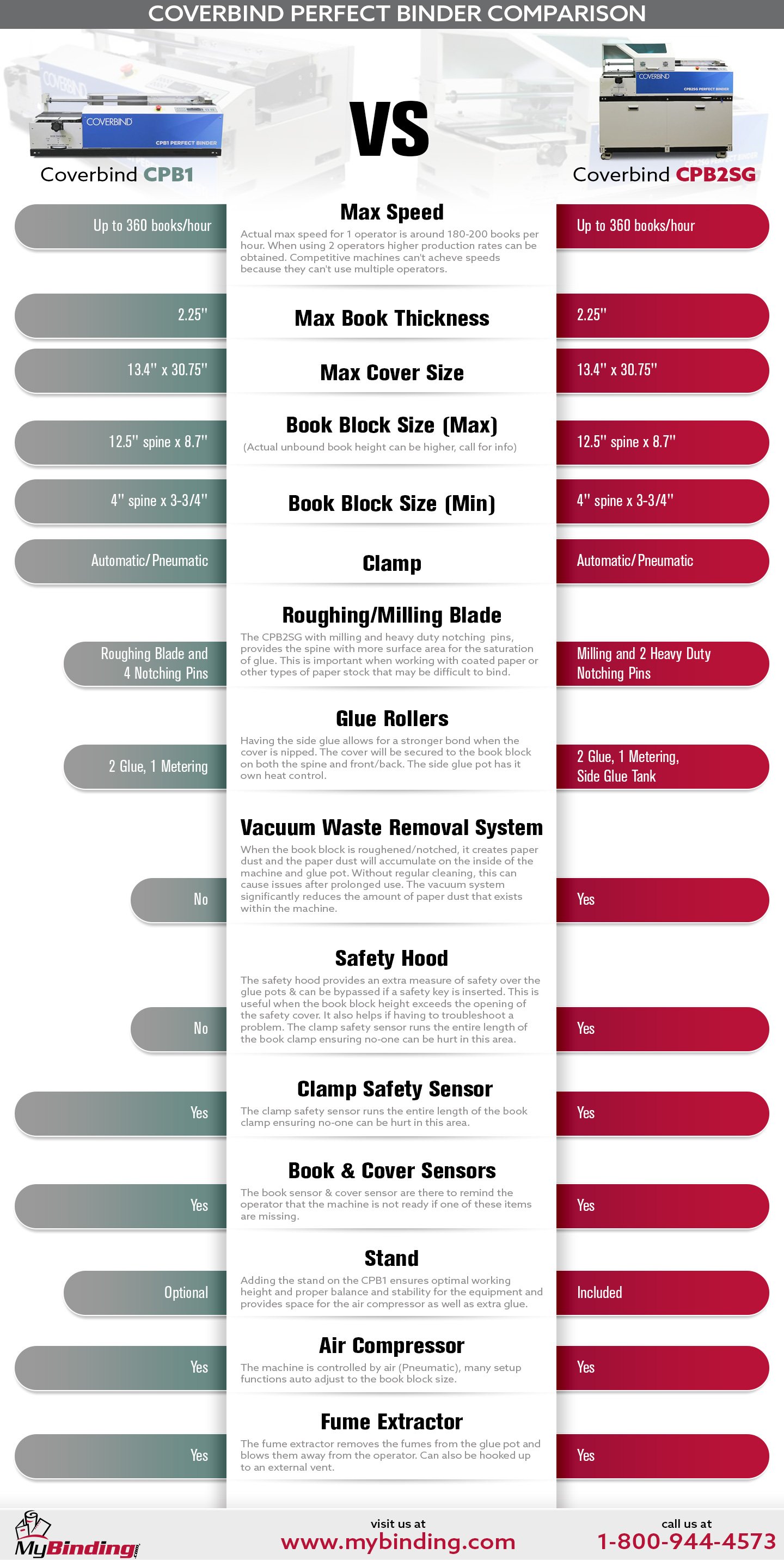

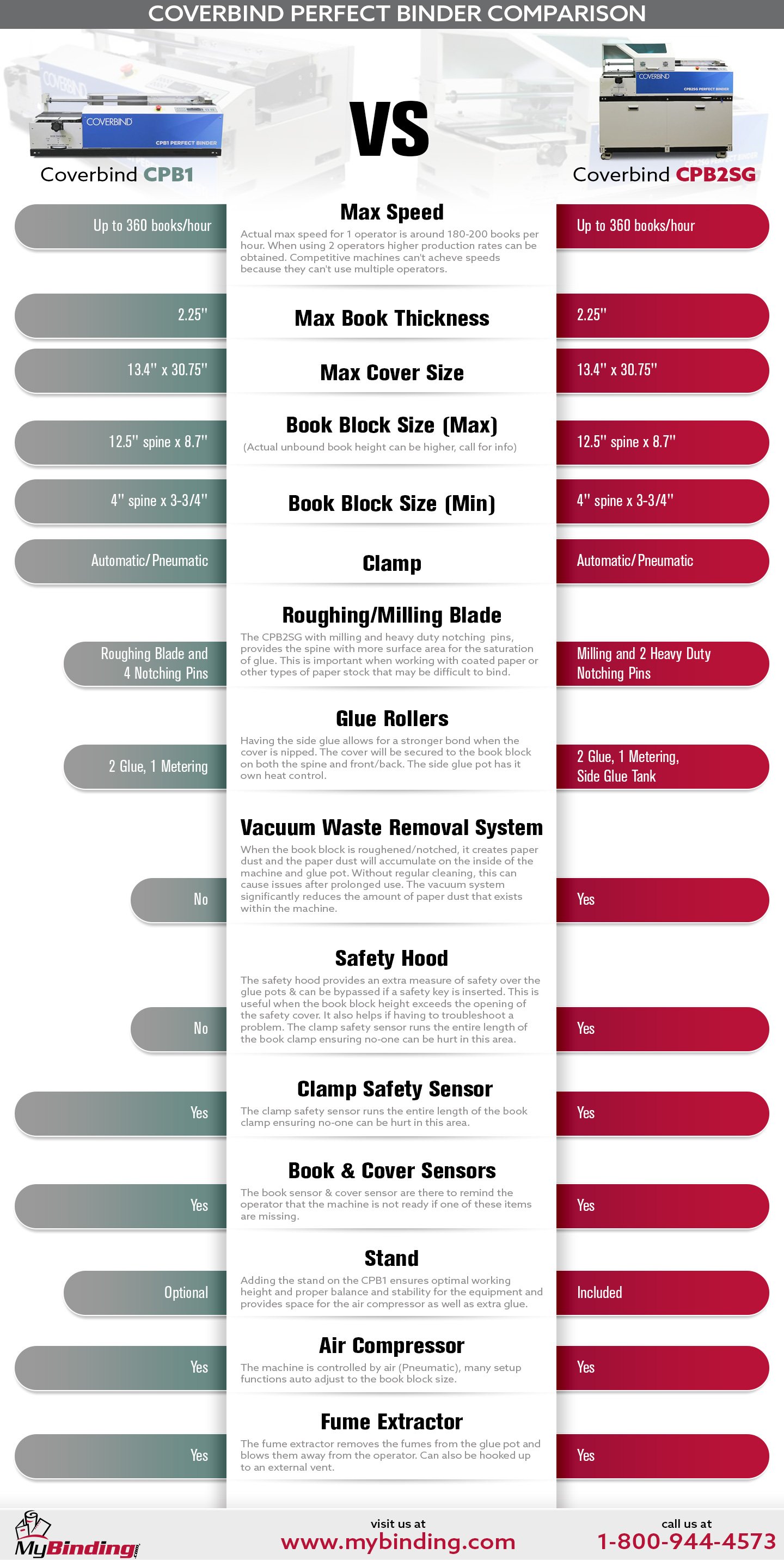

| Feature | CPB1 | CPB2SG | Benefit |

|---|---|---|---|

| Max Speed | Up to 360 books/hour | Up to 360 books/hour | Operating at an actual maximum speed of 10-200 books per hour, higher production rates can be obtained with additional operators. This feature cannot be done by other competitive machines as they are not designed for multiple operators. |

| Max Book Thickness | 2.25" | 2.25" | |

| Max Cover Size | 13.4" x 30.75" | 13.4" x 30.75" | |

| Book Block Size (Max) | 12.5" spine x 8.7" | 12.5" spine x 8.7" | (Actual unbound book height can be higher, call for info) |

| Book Block Size (Min) | 4" spine x 3-3/4" | 4" spine x 3-3/4" | |

| Clamp | Automatic/Pneumatic | Automatic/Pneumatic | |

| Roughing/Milling Blade | Roughing Blade and 4 Notching Pins | Milling and 2 Heavy Duty Notching Pins | Adding strength to the spine is Roughing/Milling Blade. The CPB2SG is equipped with milling and heavy-duty notching pins to give the spine more surface area for the glue to settle on. This is very important in binding coated paper and other difficult-to-bind paper stocks. |

| Glue Rollers | 2 Glue, 1 Metering | 2 Glue, 1 Metering, Side Glue Tank | Ensure a stronger bond with Glue Rollers. The CPB1 and CPB2SG all have 2 Glue Rollers and 1 Metering. Model CPB2SG have the Side Glue Tank. The side glue provides a stronger bond when the cover is nipped, this secures the cover to the book block on both the spine and front/back. To add, the side glue pot has built-in heat control. |

| Vacuum Waste Removal System | No | Yes | Keep the workplace clean and tidy with the Vacuum Waste Removal System. The system gathers paper dust produced during the roughening and notching process. This prevents the accumulation of dust inside the machine and glue pot. Having a Vacuum Waste Removal System prevents issues and damages that come with the prolonged accumulation of dust. |

| Safety Hood | No | Yes | An added feature protecting operators from accidents is the Safety Hood. The Safety Hood limits access over the glue pots, it is beneficial when the book block height goes beyond the opening of the safety cover. The Safety Hood is bypassed only when a safety key is inserted. Another benefit of the Safety Hood is it provides access to troubleshooting problems. A clamp safety sensor runs the entire length of the book clamp to ensure overall safety within the area. |

| Clamp Safety Sensor | Yes | Yes | Ensuring no accident happens within the book clamp is the Clamp Safety Sensor. The sensor runs the entire length of the area to make sure nothing comes into contact with the area during operation. |

| Book & Cover Sensors | Yes | Yes | Assisting the operator in making sure nothing is missed is the Book and Cover Sensor. The sensor reminds the operator that the binder is not ready to operate if the book or cover is missing. |

| Stand | Optional | Included | The CPB1 does not come with a stand. Having a stand provides optimal working height, proper balance, and stability. It also offers more space for the compressor and also storage for glue supply. |

| Air Compressor | Yes | Yes | Pneumatic control offers convenience and speed as its auto-adjust setup functions in handling book block size. |

| Fume Extractor | Yes | Yes | Protecting operators from smells and odors from the machine is the Fume Extractor. The Fume Extractor removes fumes from the glue pot and away from the operator. It can be hooked to an external vent to keep the workplace free from fumes. |

| Automatic Cover Creaser | No | No | An Automatic Cover Creaser reduces cracks in the fold site of digitally printed covers. This function preserves and elevates the final look of the book especially when the cover is pulled back. Having this feature eliminates the need to process on a separate creasing machine thus cutting costs. |

| Creasing Bar | No | No | Choose from a selection of creasing depths suited for every medium from the Creasing Bar. The Creasing Bar can be rotated in four directions to select the chosen creasing depth. |

| Automatic Cover Feeder | No | No | The Automatic Cover Feeder significantly elevates the workflow by taking advantage of embedded sensors to automatically feed the cover into position when it is ready for binding. The same sensors also detect double feeds and missing covers ensuring that each binding cycle is complete. |