Fastbind Ha10 Corner Cutter

FAQ: 0 Questions, 0 Answers

0 Q&As

Item# FBCORCUT

- Cut the four corners of your cover in an even and accurate way.

- Speed up your work.

- Constant sharp cuts.

- Easy to clean.

Product Name

Item Number

Price

Qty

ProductDescription

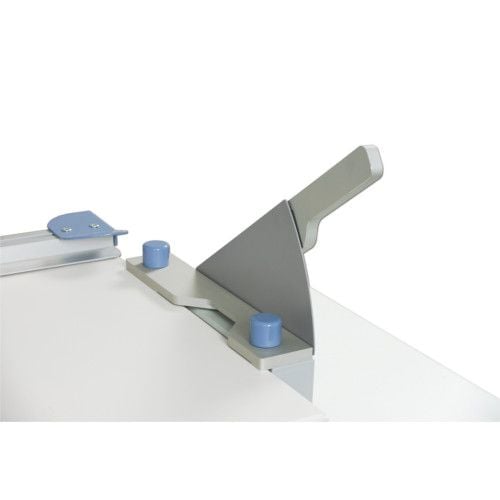

To make a perfect hard cover or case, you need to cut the corners at an exact 45 degree angle, 3 mm form the edge, to get the consistent professional results your customers demand. Fastbind Corner cutter Ha10 allows you to cut the four corners of your cover in an even and accurate way. It is adjustable according to the thickness of the cover boards. The new design makes it easy to clean the cutting blades. The Ha10 is compatible with all Fastbind Casematics.

Product Details

- Cut the four corners of your cover in an even and accurate way.

- Speed up your work.

- Constant sharp cuts.

- Easy to clean.

Item Specifications

- Product Type: Corner Cutter

- Compatible With: All Fastbind Casematics

- Warranty: 1 Year On All Parts

- Part Number: FBCORCUT

Demonstration Video

Fastbind Ha10 Corner Cutter

Transcript :

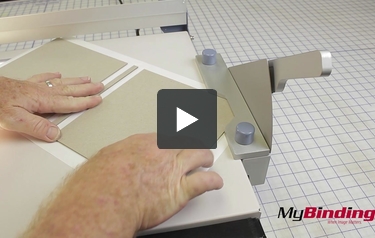

This is the Fastbind Ha10 Corner Cutter.

All the corners of your hardcovers need to be trimmed at a 45 degree angle, 3 millimeters from the corner of the board.

Now, instead of guesstimating each cut at slow pace, you can use the corner cutter. Simply slide a corner in, and make a perfect cut every time.

By placing the board up against the cutter, it makes a perfect 45 degree cut, 3 millimeters from the board’s corner. It’s easy to slide and twist your cover from corner to corner, quickly making the cuts and saving you time.

All the corners of your hardcovers need to be trimmed at a 45 degree angle, 3 millimeters from the corner of the board.

Now, instead of guesstimating each cut at slow pace, you can use the corner cutter. Simply slide a corner in, and make a perfect cut every time.

By placing the board up against the cutter, it makes a perfect 45 degree cut, 3 millimeters from the board’s corner. It’s easy to slide and twist your cover from corner to corner, quickly making the cuts and saving you time.

Fastbind Ha10 Corner Cutter Assembly

Transcript :

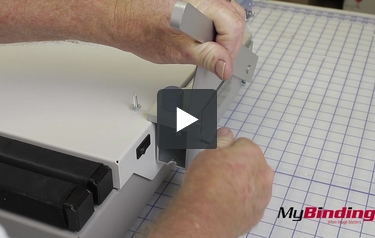

To initially assemble your Ha10 Corner Cutter, first pop off the plastic caps on each end.

Next, on the side with the handle, stick the provided allen wrench in the first hole, and place the screw on through the opening. Push the screw into the opposite hole, align it to the machine, and loosely screw it in place.

Do the same on the other side, using the hole on the handle side to align the screw to the machine. Continue to tighten both sides, and place the plastic caps back on.

Next, on the side with the handle, stick the provided allen wrench in the first hole, and place the screw on through the opening. Push the screw into the opposite hole, align it to the machine, and loosely screw it in place.

Do the same on the other side, using the hole on the handle side to align the screw to the machine. Continue to tighten both sides, and place the plastic caps back on.