-

Model NameModelHopper CapacityVariable SpeedPaper SizePowerDimensionsWeightSafety CertificationsWarranty

-

AutoSeal FD 2096

Up to 350 sheets 24#Up to 30,000 forms per hourUp to 12" wide, up to 17" long120V 60Hz, 30Amp86" L x 28" W x 42" H450 lbsN/A90 day limited warranty on parts, excluding wearables and labor

Up to 350 sheets 24#Up to 30,000 forms per hourUp to 12" wide, up to 17" long120V 60Hz, 30Amp86" L x 28" W x 42" H450 lbsN/A90 day limited warranty on parts, excluding wearables and labor -

AutoSeal FD 2200-10

N/AFixed speed of 40,000 forms/hrUp to 11.5" wide240V, Single Phase25" W x 24" L x 38.5"-39" H180 lbsN/A90 day limited warranty on parts. Excluding wearables and labor.

N/AFixed speed of 40,000 forms/hrUp to 11.5" wide240V, Single Phase25" W x 24" L x 38.5"-39" H180 lbsN/A90 day limited warranty on parts. Excluding wearables and labor. -

AutoSeal FD 2300 Series

FD 2300 (AutoSeal High-Volume Production Pressure Sealer - Air Feed Table): Up to 500 Sheets 24# (90gsm)

FD 2300 (AutoSeal High-Volume Production Pressure Sealer - Air Feed Table): Up to 500 Sheets 24# (90gsm)

FD 2300-EX (AutoSeal High-Volume Production Pressure Sealer - Extended Air Feed Table): Up to 1,000 Sheets 24# (90gsm)

FD 2350 (AutoSeal High-Volume Production Pressure Sealer - Pile Feeder): Up to 3,500 Sheets 24# (90gsm)

FD 2380 (AutoSeal High-Volume Production Pressure Sealer - Continuous Form with FD 676 Burster): Continuous FormsUp to 43,000 sheets per hour – based on 11" Z-Fold (279mm)FD 2300/2350/2380: Up to 11.5" W x 25" L

FD 2300-EX: Up to 11.5" W x 14" L208V, three phase, 20 Amp(Special 3 Phase Power Required) NEMA L14-20P plug included, NEMA L14-20R receptacle requiredCut-sheet models: 152" L x 30" W x 56" H

FD 2380: 167" L x 30" W x 56" HApprox. 1,200 lbsUL applied for90 day limited warranty on parts. Excluding wearables and labor.

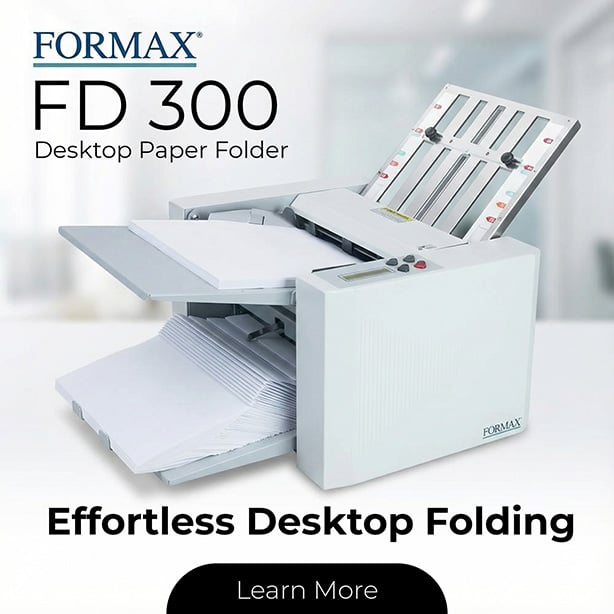

Formax AutoSeal FD 2200-10 Stand-Alone High-Volume Pressure Sealer

FAQ: 0 Questions, 0 Answers

0 Q&As

Item# FD2200-10

- Stand-Alone Sealing System: Specifically designed for use with various high-production floor model folders

- Heavy Duty Construction: Designed for high-volume production environments such as direct mail and fulfillment centers

- Pressure Rollers: High-production precision ground clutching four-roller system

- Fault Detection: Infrared sensor located at the infeed of the sealer detects any faults and sends signal to stop the upstream folder it's connected to

ProductDescription

The Formax FD 2200-10 Stand Alone pressure sealer is the ideal solution for high volume mailers who want to utilize existing floor model folding systems. The ability to purchase a "sealer-only" system versus a complete folding and sealing solution drastically reduces the up-front capital needed to add pressure seal as a new solution for your customers. The 2200-10 utilizes a patended pressure seal system that has been carefully engineered and refined to process pressure seal forms at speeds of up to 40,000 pieces per hour in the most demanding environments.

Product Details

- Stand-Alone Sealing System: Specifically designed for use with various high-production floor model folders

- Heavy Duty Construction: Designed for high-volume production environments such as direct mail and fulfillment centers

- Pressure Rollers: High-production precision ground clutching four-roller system

- Fault Detection: Infrared sensor located at the infeed of the sealer detects any faults and sends signal to stop the upstream folder it's connected to

- Clutching Roller System: Clutching roller system reduces belt and motor wear when double-feeds are detected

- Safety Cover Interlock: Shuts down the system when the cover is open

- Static Eliminator: Static brush is located on the exit of the sealer to reduce static electricity and assist in the neat, sequential stacking of forms onto a conveyor

- Interface Connections: Three interface connections for power input, signal input and fault detection output

- Plexi-Cover: Allows operators to watch forms pass through the sealer. The cover is hinged with a handle to allow quick access to the sealing area

- 8-Ball Transport Deck: 10" ball-deck provides smooth, enclosed transport of the form from the folder rollers into the sealer

- Heavy Duty Casters: Adjustable height - 2 fixed locking casters, 2 swivel casters

- Mounting Bracket: Securely attaches the FD 2200-10 sealer to the folder

Item Specifications

- Speed: Fixed speed of 40,000 forms/hr

- Paper Size: Up to 11.5" wide

- Dimensions FD 2200-10: 25" W x 24" L x 38.5"-39" H

- Weight: 180 lbs

- Motor: 1/2 HP AC

- Power: 240V, Single Phase

- Power Input Connection: 240V, Single Phase

- Signal Input Connection: 240V to start relay

- Fault Detection Connection: 24V

- Manufacturer's Warranty:

- 90 day limited Manufacturer's Warranty on parts.

- Excluding wearables and labor.

Demonstration Video

Formax AutoSeal FD 2200 High-Volume Pressure Sealer Demo Video

Transcript :

The 2200 series high-volume production pressure sealers are available in four models. Each model utilizes an automatic folder that can be set with the touch of a button. Let's take a closer look at the FD 2250 and FD 2280. The FD 2250 utilizes a vacuum pile feed system that can hold up to 3,000 pressure seal forms as seen here. The folder system is operated by the centrally located control panel. Here you can automatically set your fold type, form length speed, save custom jobs, and keep an accurate count of forms processed. The fold type and form length are selected by simply pressing a few b ...

The 2200 series high-volume production pressure sealers are available in four models. Each model utilizes an automatic folder that can be set with the touch of a button. Let's take a closer look at the FD 2250 and FD 2280. The FD 2250 utilizes a vacuum pile feed system that can hold up to 3,000 pressure seal forms as seen here. The folder system is operated by the centrally located control panel. Here you can automatically set your fold type, form length speed, save custom jobs, and keep an accurate count of forms processed. The fold type and form length are selected by simply pressing a few buttons. The folder utilizes four heavy-duty fold plates that can be set to accommodate several different fold types and output orientation important to numbered applications such as payroll. As seen here, heavy-duty combination fold rollers are utilized for high-volume durability and a longer folding life. These features make the 2200 series the ultimate solution for fortune 500 companies and mail houses requiring heavy-duty industrial equipment for fast and reliable performance. To operate the FD 2250, begin by turning on the main power. Next, load your forms onto the pile feeder, then select your job settings utilizing the control panel. Press the green and red folder start button followed by the pile feed activation button and then the feeder start button to begin feeding forms. Finally, adjust to desired speed. Watch how the pile feeder slowly rises as the forms are being fed. As the forms exit the seal rollers, notice how they're stacked in a neat sequential order on the output stacker. The stacker has its own set of controls that can start and stop the machine for unloading of mail ready pieces. The FD 2280 combines the FD 2200 folder and sealer with the Formax Maxi Burster to create an inline high volume production solution for processing continuous pressure seal forms. In addition to the industrial-strength folder and sealer, a heavy-duty ball transport deck is utilized for a smooth and reliable transition from the burster to the folder portion of the FD 2280, as shown here. To begin setup and operation, turn the burster, folder, sealer, and conveyor to the on position. Begin by setting the folder for the appropriate fold type and form length as shown previously on the 2250. Then, load the forms into the burster, loosen the knobs on the steel tractor feeders to adjust for the paper width, align the pin holes on the side of the forms with the pins on the tractors and lower the covers. Next, loosen the knobs on the heavy-duty slitters so they're set to cut the pin feed off the side of the form then press the form length adjuster to set the burster to burst the selected paper size. Now, press the jog button to be sure the forms are set properly. All set. Press the green start button on the burster to begin processing forms. High-volume continuous form applications are trimmed, folded, and sealed all in one pass eliminating unneeded paper handling.