Transcript:

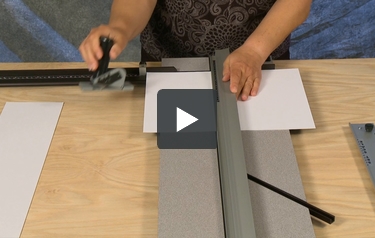

Included with the Simplex Elite Mat Cutter is a base board, a hinging guide rail, production stops, a parallel mat guide in aluminum channels, and a 27”squaring arm with production stop. It also includes a pull style bevel cutting head with anti crawl pin, start and stop indicator, and nylon guides that allow it to hook on to the side of the guide rail. Also included is a pull style straight cutter with 3 depth settings. It also includes nylon guides that allow it to hook on to the side of the guide rail. Also included is a glass cutting head with a hardened steel wheel. It also connects ...

Read More

Included with the Simplex Elite Mat Cutter is a base board, a hinging guide rail, production stops, a parallel mat guide in aluminum channels, and a 27”squaring arm with production stop. It also includes a pull style bevel cutting head with anti crawl pin, start and stop indicator, and nylon guides that allow it to hook on to the side of the guide rail. Also included is a pull style straight cutter with 3 depth settings. It also includes nylon guides that allow it to hook on to the side of the guide rail. Also included is a glass cutting head with a hardened steel wheel. It also connects to the side of the guide rail and comes with a small bottle of cutting fluid. Also included is a Plexi acrylic cutter with a fold out blade. Also included is a paper trimmer. This too will connect into the guide rail. The last of the accessories is an 8-ply bevel cutter. It features nylon guides, and anti crawl button, and start and stop indicators. It too will hook onto the side of the guide rail. To install the aluminum mat guide channels, find the rounded end and place that into the slot towards the center of the base board. Flip the base board over and using the small screws provided, install the screws in from the bottom of the board into the mat guide channels. To install the squaring arm, place the squaring arm into the board slot at the bottom of the machine. Insert the squaring arm in from the side of the board until the slot and the squaring arm lines up perfectly with the slot in the base board. Then tighten the screw to secure the squaring arm in place. To install the squaring arm production stop, slide it on to the bar from the end of the squaring arm. With the knobs loosened, install the parallel mat guide into the channels. To install a blade into the pull style bevel cutting head, first loosen the retaining screw on the back of the cutting head. Then loosen the blade knob. Insert one blade sharp side down into the blade holder. Then retighten the blade knob. Rotate the blade holder down and retighten the retaining screw. To adjust the blade depth, find the blade depth adjustment screw on the bottom of the cutting head. Using a screwdriver, turn the screw clockwise to decrease the blade depth or counterclockwise to increase the blade depth. See that the blade is barely passing through the mat board and only scoring into the slip sheet. To install a blade on to the straight cutter, first remove the blade knob. Also remove the blade cover. Install a single blade sharp side down onto the blade holder. Then replace the blade cover and the blade knob. The straight cutter features 3 different depth settings for storage, standard thickness mat board, and 3/16” foam board. To downsize a piece of mat board, first remove the slip sheet. Also remove the parallel mat guide. Insert a mat blank color side down into the machine down against the squaring arm and out to the number needed. Then slide the production stop and lock it in place. Too set the depth on the straight cutter, loosen the blade knob and slide it out to the middle or standard thickness mat board setting. Hook the straight cutter onto the rail and pull back to make the cut. To bevel cut an opening, first remove the slip sheet and set the parallel mat guide to the boarder size needed, in this example, 3”. Always ensure that the slip sheet is in the machine when bevel cutting. Insert the mat blank color side down up against the parallel mat guide. Using a pencil, mark all 4 lines on the back of the mat. Now see that the mat guide is against the parallel mat guide and against the squaring arm. Hook the bevel cutter onto the guide rail and align the start and stop indicator with the pencil line. Depress the anti crawl button, rotate the blade in, release the anti crawl button, and pull back to the bottom line. Repeat this process for all remaining three sides. After the 4th cut, the window will drop out and you will have a perfectly beveled mat. To bevel cut a mat using production stops, remove the slip sheet and set the mat guide to the boarder size needed, in this example, 3”. Always use a slip sheet when bevel mat cutting. Insert the mat blank color side down against the parallel mat guide. Use a pencil to mark one single line on the back of the mat. Turning the mat clockwise, put the mat against the parallel mat guide and down against the squaring arm. Now set the bottom production stop to the same size 3” boarder. Hook the bevel cutting head onto the rail and align the start and stop indicator with a pencil line. Press the anti crawl button, rotate the blade in, release the anti crawl button, and pull back to the bottom stop as you continue the cut line in the back of the mat references where your next cut starts. Repeat this process for all remaining sides. After the fourth cut, the window will drop out and you will have a perfectly beveled mat. To size glass using the glass cutter, first remove the slip sheet and the parallel mat guide. Always use gloves when handling glass. Insert the glass to be sized into the machine placing the edge of the glass along the squaring arm number that the glass is to be cut to. Add a drop of cutting fluid to the glass cutting wheel. Now hook the glass cutter onto the rail until the wheel is just over onto the edge of the glass. Using moderate pressure downward, pull across the glass described. Slide the glass out so the scribe line is along the edge of the base board and press down to snap off. To trim Plexiglas in the Simplex mat cutter, first remove the slip sheet and the parallel mat guide. Insert the Plexiglas into the machine with the edge along the squaring arm number that you wish to size it to. Set the guide rail down and with the tip of the Plexiglas cutter, make three passes scoring the Plexiglas. After scoring, flip the Plexiglas over and reinstall it into the machine with the scribe lined up with the guide rail. Putting pressure down on the guide rail, lift up on the Plexiglas to snap off the sized piece. To size paper on your Simplex mat cutter using the paper trimmer, first remove the mat guide but leave the slip sheet in place. Insert your paper into the machine with the edge of the paper on the squaring arm number you wish to size the paper to. Set the guide rail down and connect the paper trimmer into the near end of the guide rail. Slide it to the far end of the paper and pushing down on the forward edge of the paper trimmer, pull straight back to size your paper. To install a blade into the 8-ply cutter, first loosen the blade holding knob, then remove the blade holding magazine. Install one Logan number 271 blade onto the magnetic magazine. Reinsert into the blade holder and retighten the blade knob. To adjust the blade depth on the 8-plu mat cutter, loosen the blade knob and remove the blade holding magazine. Using the neural blade depth adjustment screw, turn the screw clockwise or counterclockwise to increase or decrease the blade depth. Then reinstall the blade holding magazine and retighten the blade holding knob. See that the blade depth is just barely passing through the thickness of the mat board and only scoring into the slip sheet. To cut an 8-ply mat, first set the mat guide to the boarder size needed, in this example, 2”. Now insert the mat blank into the machine, set down the guide rail, and mark all four boarders. Hook the 8-ply mat cutter onto the rail and line up the green start line with the pencil line. Holding down the anti crawl pin, insert the blade, release from the anti crawl pin, and pull back to the red line. Always make sure to rotate the blade out of the mat before lifting the guide rail. Repeat this process for the remaining 3 sides. After the final cut, you will have a perfectly beveled 8-ply mat. When using the machine with the squaring arm, it’s important to see that the guide rail and the squaring arm itself form a perfect 90 degree angle. To check this, use an L-shaped carpenter square. Place it into the corner of the machine to check for any gaps or movement. In this example, it shows that the squaring arm needs to be adjusted. To adjust the squareness of the squaring arm, first loosen the screw on the squaring arm clip and remove the squaring arm from the machine. Find the two adjustment screws down on the board slot. In this example, the screw on the right needs to be turned in slightly. And then the screw on the left needs to be turned out the same distance. Then replace the squaring arm into the machine. Then recheck the square using the L-shaped carpenter square to see if further adjustments are necessary.

Light32" (81cm)No3/4" (1.9cm)4 1/2" (11.4cm)YesNoPush StyleYes - 500 Mat Knife4 Ply Standard Mat Board and 3/16" (5mm) Foam Board

Light32" (81cm)No3/4" (1.9cm)4 1/2" (11.4cm)YesNoPush StyleYes - 500 Mat Knife4 Ply Standard Mat Board and 3/16" (5mm) Foam Board Moderate32" (81cm)Yes (Squaring Bar)3/4" (1.9cm)4 1/2" (11.4cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board and 3/16" (5mm) Foam Board

Moderate32" (81cm)Yes (Squaring Bar)3/4" (1.9cm)4 1/2" (11.4cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board and 3/16" (5mm) Foam Board Medium40" (101cm)Yes (Squaring Bar)3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board and 3/16" (5mm) Foam Board

Medium40" (101cm)Yes (Squaring Bar)3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board and 3/16" (5mm) Foam Board Medium40" (101cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board and 3/16" (5mm) Foam Board

Medium40" (101cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board and 3/16" (5mm) Foam Board Medium60" (152cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board and 3/16" (5mm) Foam Board

Medium60" (152cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board and 3/16" (5mm) Foam Board High40" (101cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board269, 268

High40" (101cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board269, 268 High48" (121cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board269, 268

High48" (121cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board269, 268 High60" (152cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board269, 268

High60" (152cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board269, 268 High40" (101cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board and 3/16" (5mm) Foam Board Sizing Glass, Plexi Acrylic, and Paper270, 271, 786, 2038

High40" (101cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board and 3/16" (5mm) Foam Board Sizing Glass, Plexi Acrylic, and Paper270, 271, 786, 2038 High60" (152cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board and 3/16" (5mm) Foam Board Sizing Glass, Plexi Acrylic, and Paper270, 271, 786, 2038

High60" (152cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwoPush StyleYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board and 3/16" (5mm) Foam Board Sizing Glass, Plexi Acrylic, and Paper270, 271, 786, 2038 High40" (101cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board267

High40" (101cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)5 1/2" (14cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board267 High48" (121cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)8" (20.3cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board267

High48" (121cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)8" (20.3cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board267 High60" (152cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)8" (20.3cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board267

High60" (152cm)Yes 32" (81cm) Squaring Bar3/4" (1.9cm)8" (20.3cm)YesTwo (Movable)Push Style Dual Purpose Bevel and Straight CutterYes - 701-1 Straight Cutter4 Ply Standard Mat Board, 8 Ply Mat Board, 3/8" (10mm) Foam Board267