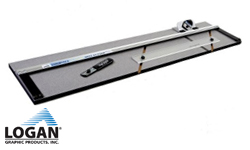

Foam Board Straight / Bevel Cutter by FoamWerks - WC6010

FAQ: 0 Questions, 0 Answers

0 Q&As

Item# WC6010

- Economy and versatility.

- Features include adjustable blade depth, ergonomic handle and on-board blade storage.

- Works with 3/16" (5mm) foam board.

- Includes two blades and can be used with any suitable straight edge.

Product Name

Item Number

Price

Qty

ProductDescription

Economy and versatility combine in the FoamWerks Straight/Bevel Cutter. Simply rotate the angled base block and Model WC-6010 transforms from a straight cutter to a bevel cutter. Features include adjustable blade depth, ergonomic handle and on-board blade storage. The Straight/Bevel Cutter works with 3/16" (5mm) foam board. The Straight/Bevel Cutter includes two blades and can be used with any suitable straight edge. Use replacement blades WC-5 or WC-20.

IMPORTANT: Always use a scrap piece of foam board underneath the piece you are cutting. This is to protect the tool and extend the life of the blades.

Product Details

Demonstration Video

FoamWerks WC-6010 Straight Bevel Demo

Transcript :

To install a blade onto the Logan FoamWerks Straight Bevel Cutter, remove a single blade from the blade storage area. Now remove the blade-holding knob, lay the blade on the side of the tool, and replace the blade-holding knob. The tool is now ready to cut at a 90-degree angle. To convert the Straight Bevel Cutter to a bevel cutter, remove the blade and install it on the other side of the tool. Then loosen the base block knob and rotate the base 180 degrees. Now the tool is ready to cut a 45-degree bevel. To set the blade depth, loosen the blade and reference the back edge of the blade on the ...

To install a blade onto the Logan FoamWerks Straight Bevel Cutter, remove a single blade from the blade storage area. Now remove the blade-holding knob, lay the blade on the side of the tool, and replace the blade-holding knob. The tool is now ready to cut at a 90-degree angle. To convert the Straight Bevel Cutter to a bevel cutter, remove the blade and install it on the other side of the tool. Then loosen the base block knob and rotate the base 180 degrees. Now the tool is ready to cut a 45-degree bevel. To set the blade depth, loosen the blade and reference the back edge of the blade on the hash marks found on the tool. To produce a 90-degree straight cut using the Logan FoamWerks Straight Bevel Cutter, always make sure you have scrap foam board under the foam board you’re going to cut. Use the channel rails as straight edge to guide the tool. Start with the tool just past the edge of the foam board. Hold tightly against the straight edge and pull straight back to make a straight cut. When finished, always loosen the blade and put it back to a safety position. To make a 45-degree cut using the Logan Straight Bevel Cutter, first always ensure that you’re using a scrap piece of foam board under the foam board you are cutting. Use the Logan channel rail as a straight edge to guide the tool. Extend the blade to the proper blade depth. Hold the tool firmly against the straight edge and pull straight back to make your bevel cut.After finishing your cut, see that you replace the blade to the safety setting.