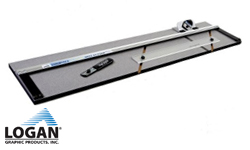

Foam Board Straight Cutter by FoamWerks - WC6001

FAQ: 0 Questions, 0 Answers

0 Q&As

Item# WC6001

- Cut perfect straight edges on any depth of foam board from 1/8" to 1/2" (3.1mm to 12.7mm).

- Features adjustable blade depth, quick change blade clip, magnetic blade slot, on-board blade storage drawer and five blades.

- Use with FoamWerks Channel Rail, Logan Adapt-A-Rule or Team System.

- Use replacement blades WC-5 or WC-20.

Product Name

Item Number

Price

Qty

ProductDescription

The Foam Board Straight Cutter by FoamWerks can cut perfect straight edges on any depth of foam board from 1/8" to 1/2" (3.1mm to 12.7mm). FoamWerks Straight Cutter features adjustable blade depth, quick change blade clip, magnetic blade slot, on-board blade storage drawer and five blades. Use with FoamWerks Channel Rail, Logan Adapt-A-Rule or Team System. Use replacement blades WC-5 or WC-20.

IMPORTANT: Always use a scrap piece of foam board underneath the piece you are cutting. This is to protect the tool and extend the life of the blades.

Product Details

- Cut perfect straight edges on any depth of foam board from 1/8" to 1/2" (3.1mm to 12.7mm).

- Features adjustable blade depth, quick change blade clip, magnetic blade slot, on-board blade storage drawer and five blades.

- Use with FoamWerks Channel Rail, Logan Adapt-A-Rule or Team System.

- Use replacement blades WC-5 or WC-20.

- 90 Days Manufacturer's Warranty

Demonstration Video

FoamWerks WC-6001 Straight Cutter Demo

Transcript :

To install a blade onto the Logan FoamWerks Straight Cutter, first remove the yellow blade cover clip. Install a blade using the magnet to hold it in place, and replace the yellow blade-holding clip. Note the extra blade storage on the back of the tool. The FoamWerks Straight Cutter will connect itself to the side of the Logan FoamWerks Channel Rail. The Straight Cutter can also be used left-handed by switching the blade to the other side of the tool.To adjust the blade depth on the Logan FoamWerks Straight Cutter, find the dial on the back. This adjusts the gauge on the bottom of the tool fro ...

To install a blade onto the Logan FoamWerks Straight Cutter, first remove the yellow blade cover clip. Install a blade using the magnet to hold it in place, and replace the yellow blade-holding clip. Note the extra blade storage on the back of the tool. The FoamWerks Straight Cutter will connect itself to the side of the Logan FoamWerks Channel Rail. The Straight Cutter can also be used left-handed by switching the blade to the other side of the tool.To adjust the blade depth on the Logan FoamWerks Straight Cutter, find the dial on the back. This adjusts the gauge on the bottom of the tool from shallow to deeper. To use the Straight Cutter, first make sure that you’re using a scrap piece of foam board under the foam board that you’re going to cut. Use the Logan FoamWerks Channel Rail to mark a reference line where the straight cut is to appear. Turn the rail around so the raised edge aligns along your reference mark, and hook the straight cutter onto the side of the rail. By depressing the front edge of the straight cutter and pulling back, you will [now downsize – 01:42] the foam board.