Triumph 7260 28" Automatic Programmable Hydraulic Paper Cutter with VRCut Software

FAQ: 1 Questions, 1 Answers

1 Q&As

Item# CU0494

- Cutting Width: 28"

- Cutting Height: 3"

- Narrow Cut: 3/4" (3 1/2 with false clamp)

- Cutting Length Behind Blade: 28"

ProductDescription

This Triumph 7260 is a 28 inch programmable paper cutter with hydraulic clamp, power back gauge, 7-inch touch pad control module, and IR safety light beams on front table. The Triumph 7260 has a programmable control module for the power backgauge with multi-lingual touch pad, and 99 programs with 99 steps in each program can be stored. The convenient, drop-in tool holder is located on the rear of the machine and keeps all tools necessary for routine maintenance(including blade changes) within reach. Its Patented EASY CUT blade activation bars ensure true, two-hand operation and allow blade and clamp to be activated independently. Plus, blade changes can be made without removing the machine covers. The Triumph 7260 now comes with a NEW VRCut PC software solution designed to automate the cutting work-flow by promoting an efficient and error-free cutting process from start to finish. VRCut intelligently bridges the gap between pre-press and the finishing process, allowing operatorsof an experience level the ability to cut with confidence. Increase your work productivity and output with this Triumph 7260 28" Automatic Programmable Hydraulic Paper Cutter.

Product Details

- IR Safety Curtain. The IR light beam safety curtain covers the work area to ensure the highest level of operator safety.

- Electronic Hand Wheel. The electronic hand wheel, with infinitely variable speed control, is used for manual back gauge positioning.

- Easy Cut Blade Activation Bars. Patented EASY CUT blade activation bars ensure true, two-hand operation and allow blade and clamp to be activated independently.

- Programmable Back Gauge The control module for the power back gauge can store 99 programs with up to 99 steps in each.

- Tool Holder. Convenient, drop-in tool holder is located on the rear of the machine and keeps all tools necessary for routine maintenance (including blade changes) within reach.

- Safe Blade Changes. Blade changes can be made without removing the machine covers. The handy blade changing device covers the cutting edge of blade.

- VRCUT Impose:

- A barcode is automatically created that can be scanned for error-free job recall on the Triumph cutter.

- As an additional guidance measure, cut sequence numbers and arrows are printed on the sheet to guide the operator.

- VRCUT Controller:

- Current step and cut-line indicator arrow are highlighted in the upper left and hand corner.

- A prominent arrow is displayed if the current step requires a rotation action from the operator.

- Full cut sequence instructions are displayed with the current step highlighted for quick reference.

- An orange line appears indicating the cut line.

- Operator is notified at each step when to discard paper scraps, save cut segments for additional cutting and set aside finished product for shipment.

- Options: Side Tables (CU0441), Cutting Knives (AC0657), Cutting Sticks (AC0671)

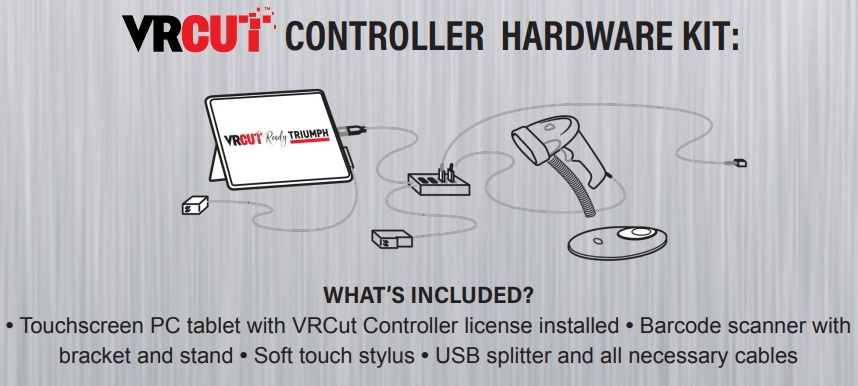

- Comes with FREE VRCut Controller Hardware Kit:

- After registering your VRCut license you have the option to order a complete VRCut Controller Hardware Kit at no cost (free shipping included within the United States). The VRCut Controller Hardware Kit comes with everything you need, including a touchscreen PC tablet with VRCut Controller license installed, a barcode scanner, mount and all of the required cabling. Open the box, set up the components, and you’re ready to go!

Item Specifications

- Type of machine: Programmable Hydraulic

- Cutting Width: 28"

- Cutting Height: 3"

- Narrow Cut: 3/4" (3 1/2 with false clamp)

- Cutting Length Behind Blade: 28"

- Motor Output, Horsepower: 2

- Power Supply: 220V, 3 phase

- Dimensions (D x W x H): 60 1/2" x 51 3/8" x 52 1/2" (63 D, 82 1/2 W with side tables)

- Shipping Weight: 1,534 lbs (1,622 lbs with side tables)

- Manufacturer's Warranty: 1-year limited Manufacturer's Warranty, excluding wearables

Demonstration Video

MBM VR Cut Models – How to Use the Control Panel

Transcript :

Speaker 1:

Today we're going to be demonstrating the VR Cut Controller. The VR Cut Controller will automatically guide the operator with a visual interface. To start the job, we're on a Triumph 5260. We click the start button and read the bar code on the job layout. The job layout was created in VR Cut Impose, and it automatically calls in the appropriate template. It gives the operator an option to call in the actual artwork. And that way you can actually see the-

VR Cut Controller:

Jog to squares down.

Speaker 1:

-artwork that you're heading. The backgauge moves to the first position.

...

Today we're going to be demonstrating the VR Cut Controller. The VR Cut Controller will automatically guide the operator with a visual interface. To start the job, we're on a Triumph 5260. We click the start button and read the bar code on the job layout. The job layout was created in VR Cut Impose, and it automatically calls in the appropriate template. It gives the operator an option to call in the actual artwork. And that way you can actually see the-

VR Cut Controller:

Jog to squares down.

Speaker 1:

-artwork that you're heading. The backgauge moves to the first position.

...

Speaker 1:

Today we're going to be demonstrating the VR Cut Controller. The VR Cut Controller will automatically guide the operator with a visual interface. To start the job, we're on a Triumph 5260. We click the start button and read the bar code on the job layout. The job layout was created in VR Cut Impose, and it automatically calls in the appropriate template. It gives the operator an option to call in the actual artwork. And that way you can actually see the-

VR Cut Controller:

Jog to squares down.

Speaker 1:

-artwork that you're heading. The backgauge moves to the first position.

VR Cut Controller:

Ready to cut step one.

Speaker 1:

The operator places the document into the cutter to ensure that it can cut. You'll see it will have the visual marker on the paper,-

VR Cut Controller:

Rotate 90 clockwise.

Speaker 1:

-as well as on the screen. Now they have the audio command. Visual commands to rotate the paper. Also, it alines with cut two- [crosstalk 00:01:02].

VR Cut Controller:

Scan two.

Speaker 1:

-on the paper and on the screen. You'll see lid trash can open to indicate that there's a scrap to throw away.

VR Cut Controller:

Rotate 90 clockwise.

Speaker 1:

We rotate the paper-

VR Cut Controller:

Ready to cut step three.

Speaker 1:

-throw away the scrap.

VR Cut Controller:

Ready to cut step four.

Speaker 1:

And you'll notice in this case that the table on the-

VR Cut Controller:

Ready to cut step five.

Speaker 1:

-screen has the-

VR Cut Controller:

Rotate 90 clockwise.

Speaker 1:

-has the work table. Now you take the page off the work table, rotate it, place it onto the cutter.

VR Cut Controller:

Ready to cut step six. Ready to cut step seven.

Speaker 1:

No rotation here. Now you'll notice the two pieces move over to-

VR Cut Controller:

Ready to cut step eight.

Speaker 1:

-the pallet indicating they are finished. This edge rips off the bleed edge.

VR Cut Controller:

Job complete.

Speaker 1:

And now the final two are push forward, and the job is complete.

Main Features

HIGH QUALITY BLADES All Triumph cutter models feature high quality, German steel blades. |

EASY CUT BLADE ACTIVATION BARS Patented EASY CUT blade activation bars provide true two-hand operation (models 4315 and above). |

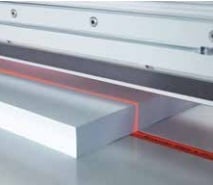

OPTICAL CUTTING LINE The optical cutting line indicator with bright LEDs ensures perfect alignment of cutting marks (models 4315 and above). |

EASY-TO-USE TOUCHPAD A multilingual, programmable touchpad module controls the back gauge on models 5255–7260. |

IR SAFETY CURTAIN The IR light beam safety curtain covers the work area to ensure the highest level of operator safety (models 5260, 6660, 5560, 7260). |

PROGRAMMABLE BACK GAUGE The 5560/5560 LT and 7260 has a 7" programmable back gauge control module capable of storing 99 programs with 99 steps each in memory. |

Comprehensive SCS Safety Package Features:

- Patented EASY CUT electronic blade activation bars for true two-hand operation.

- IR light beam safety curtain on front table.

- Safety cover on rear table.

- Main switch and safety lock with key.

- 24 volt controls (low voltage).

- Patented IDEAL safety drive.

- Automatic blade and clamp return from every position.

- Disc brake for instant blade stop.

- Blade changing device covers cutting edge of blade.

- Blade depth adjustment from outside of machine.

- Blade and cutting stick can be changed without removing covers.

Other Features:

- Hydraulic clamp drive. Foot pedal for pre-clamping.

- Digital measurement display (cm or inches) with multilingual operator guidance, accurate to 1/10 mm or 1/100 inch.

- Pre-programmed for standard paper sizes.

- Memory keys for repeat cuts (manual) and quick setting of frequently needed measurements.

- Automatic SET function for reference measurement and paper EJECT function with and without program mode.

- DELETE and INSERT mode for correcting and modifying programs.

- Automatic correction in case of back gauge displacement.

- Push buttons for fast back gauge movement (forward and reverse).

- Integrated calculator.

- Self-diagnostic system with error indication on display.

- Electric blade drive with solid steel carrier and adjustable guides.

- Electronic hand wheel with variable speed control for manual back gauge setting.

- Clamp pressure is fully adjustable between 550 and 4,400 psi. False clamp plate with optical indicator.

- Bright, LED optical cutting line. Stainless steel work surface.

- Standard air tables (front and rear).

- High quality, German HSS blade.

- Precision swing cut blade movement.

- All-metal construction.

- Includes easy-access tool holder and paper blocking tool.

- Optional side tables increase work surface.

- UL and C UL approved.

Compare to Similar Paper Cutters

| Model Name | Triumph 7260 | Triumph 5255 | Triumph 5260 | Triumph 6655 | Triumph 6660 | Triumph 5560 | Triumph 5560 LT |

|---|---|---|---|---|---|---|---|

| Model |  |

|

|

|

|

|

|

| Part Number | CU0494 | MBM-CU0490 | CU0489 | MBM-CU0491 | CU0492 | CU0493 | CU0497 |

| Cutting Width | 28" | 20 3/8" | 20 3/8" | 25 1/2" | 25 1/2" | 21 5/8" | 21 5/8" |

| Cutting Height | 3" | 3" | 3" | 3" | 3" | 3 3/4" (3 5/8 w false clamp) | 3 3/4" (3 5/8 w false clamp) |

| Narrow Cut | 3/4" (3 1/2 w false clamp) | 1 3/8" | 1 3/8" | 1" | 1" | 1 1/4" (2 3/8 w false clamp) | 1 1/4" (2 3/8 w false clamp) |

| Cutting Length Behind Blade |

28" | 20 3/8" | 20 3/8" | 24" | 24" | 22 7/16" | 22 7/16" |

| Dimensions (D x W x H) | 60 1/2" x 51 3/8" x 52 1/2" (63 D, 82 1/2 W with side tables) |

44" x 33 7/8" x 51" (56 1/2 W with side tables) |

44" x 33 7/8" x 51" (56 1/2" W with side tables) |

48" x 39" x 51" (61 1/2 W with side tables) |

48" x 39" x 51" (61 1/2 W with side tables) |

55" x 42" x 54" (64 W with side tables) |

55" x 42" x 54" (64 W with side tables) |

Questions & Answers

Great Question! So this is a plate that comes with the cutter that you install on the clamp. You use it when you have a job that might be sensitive to marking the paper when the clamp comes down. If you have any further questions, feel free to call us at 800-944-4573.

Answered by Mybinding.com