-

Model NameModelThroat CapacityMax Laminating SpeedMax Pouch ThicknessMax Laminating ThicknessHeated Roller SystemMemory SettingsSpeed ControlOperating TemperatureDimensionsWeightPower ConsumptionWarranty

-

Akiles Pro-Lam Plus 160

6.3″ (160 mm)23″ / min10 mils (250 Mic.)3/64″ (1 mm)2 Hot / 2 ColdN/AN/A176 - 320 F14.5″ x 8.5″ x 4.5″14 lbs (16 Kg)N/A1 Year

6.3″ (160 mm)23″ / min10 mils (250 Mic.)3/64″ (1 mm)2 Hot / 2 ColdN/AN/A176 - 320 F14.5″ x 8.5″ x 4.5″14 lbs (16 Kg)N/A1 Year -

Akiles Pro-Lam Plus 330

13″ (330 mm)23″ / min10 mils (250 Mic.)3/64″ (1 mm)2 Hot / 2 ColdN/AN/A176 - 320 F21″ x 8.5″ x 4.5″20 lbs (26 Kg)N/A1 Year

13″ (330 mm)23″ / min10 mils (250 Mic.)3/64″ (1 mm)2 Hot / 2 ColdN/AN/A176 - 320 F21″ x 8.5″ x 4.5″20 lbs (26 Kg)N/A1 Year -

Akiles iLam Plus

12.8″ (325mm)21″ / min10 mils (250 Mic.)3/64″ (1 mm)4 Silicone (2 Hot / 2 Cold)N/AN/A293°F (Max)19″ x 18.5″ x 4.5″15 lbs (7 Kg)550 watts1 Year

12.8″ (325mm)21″ / min10 mils (250 Mic.)3/64″ (1 mm)4 Silicone (2 Hot / 2 Cold)N/AN/A293°F (Max)19″ x 18.5″ x 4.5″15 lbs (7 Kg)550 watts1 Year -

Akiles Pro-Lam Photo

13″ (330mm)59″ / min10 mils (250 Mic.)1 mm6 Silicon Rollers (4 Heat / 2 Cold)Electronic (8-bit Micro Processor)9 Settings32 – 320°FN/A39 lbs1150W1 Year

13″ (330mm)59″ / min10 mils (250 Mic.)1 mm6 Silicon Rollers (4 Heat / 2 Cold)Electronic (8-bit Micro Processor)9 Settings32 – 320°FN/A39 lbs1150W1 Year -

Akiles Pro-Lam Ultra

13″ (330mm)53″ / min14 mil1/8″ (3 mm)6 Silicon Rollers (4 Heat / 2 Cold)7 Presets9 Settings140°C (Max)1.2 CuFt (Volume)33 lbs1150 W1 Year

13″ (330mm)53″ / min14 mil1/8″ (3 mm)6 Silicon Rollers (4 Heat / 2 Cold)7 Presets9 Settings140°C (Max)1.2 CuFt (Volume)33 lbs1150 W1 Year -

Akiles Prolam Ultra X6

13″ (330 mm)59″ / min14 mil (350 mic)1/8″ (3 mm)4 Hot / 2 Cold2 Programmable (Temperature & Speed)9 Settings32°F – 284°F21″ x 10.5″ x 5″35 lbs (16 Kg)1050 W1 Year

13″ (330 mm)59″ / min14 mil (350 mic)1/8″ (3 mm)4 Hot / 2 Cold2 Programmable (Temperature & Speed)9 Settings32°F – 284°F21″ x 10.5″ x 5″35 lbs (16 Kg)1050 W1 Year -

Akiles Prolam Ultra XL

18.9″ (480 mm)47″ / min14 mil (350 mic)1/8″ (3 mm)4 Hot / 2 Cold2 Programmable (Temperature & Speed)9 Settings32°F – 284°F27.25″ x 10.5″ x 5″44 lbs (20 Kg)1200 W1 Year

18.9″ (480 mm)47″ / min14 mil (350 mic)1/8″ (3 mm)4 Hot / 2 Cold2 Programmable (Temperature & Speed)9 Settings32°F – 284°F27.25″ x 10.5″ x 5″44 lbs (20 Kg)1200 W1 Year -

Akiles Prolam Ultra X10

13″ (330 mm)142″ / min14 mil (350 mic)1/8″ (3 mm)6 Hot / 4 Cold2 Programmable (Temperature & Speed)9 Settings32°F – 320°F14″ x 25.75″ x 5.75″57 lbs (26 Kg)1560 W1 Year

13″ (330 mm)142″ / min14 mil (350 mic)1/8″ (3 mm)6 Hot / 4 Cold2 Programmable (Temperature & Speed)9 Settings32°F – 320°F14″ x 25.75″ x 5.75″57 lbs (26 Kg)1560 W1 Year

Akiles Prolam Ultra X6 Pouch Laminator

FAQ: 3 Questions, 3 Answers

3 Q&As

Item# AKPLULTRAX6

- 13" pouch laminator

- Compatible with pouches up to 14mil thick & boards up to 1/8" thick

- Thermal & cold laminating

- Adjustable heat 32 to 284°F & adjustable speed to 59"/min

ProductDescription

The Akiles ProLam Ultra X6 laminator possesses superior quality and functionality combined with a commercial grade design. The Ultra X6 has a 6 roller system that produces professional, crystal-clear and bubble-free pouches every time. Other features of the Ultra X6 include programmable memory settings, auto shutoff, LCD control panel and a large 13" opening for larger pouch laminating.

Product Details

- Commercial Grade 6 or 10 Roller Laminators with Programmable Memory Settings

- Programmable Memory Settings: Allows you to save the ideal temperature and speed for your most frequent projects.

- Auto Shutoff: Automatically cools and shuts down the machine after usage, to prolong the life of your laminator.

- Removable Cover: Allows quick acccess to the roller with easy-to-remove thumb screws.

- LCD Control Panel: Backlit LCD display with labeled keypad makes it easy to operate.

- Setting Guide: Shows the recommend temperature and speed settings for different pouch thicknesses.

- 13" Capacities: The large 13" allows the machine to laminate a wide array of pouch sizes.

- Air Cooling System: Patented internal cooling system ensures the laminator stays cool to the touch while in use.

- Programmable Memory Settings: Memorize the ideal temperature & speed settings for your most frequently used pouches.

Item Specifications

- Throat Capacity: 13" (330 mm)

- Max Laminating Speed: 59" / min

- Max Pouch Thickness: 14mil (350 mic)

- Max Laminating Thickness: 1/8" (3 mm)

- Heated Roller System: 4 Hot / 2 Cold

- Memory Settings: 2 Programmable (Temperature & Speed)

- Speed Control: 9 Settings

- Operating Temperature: 32°F - 284°F

- Dimensions: 21" x 10.5" x 5"

- Weight: 35 lbs (16 Kg)

- Power Consumption: 1050 W

- Manufacturer's Warranty: 1 Year

- Compatible Supplies: Pouch Laminate Up to 13" Wide & 1.5-14mil Thick

Up to 1/8" Pouch Board

Demonstration Video

Akiles Prolam Ultra X6 Pouch Laminator Demo Video

Transcript :

Welcome to Mybinding video. What you see before you is the Akiles ProLam Ultra X6 Pouch Laminator. This is a heavy duty great workhorse of a machine. This pouch laminator will work with all kinds of laminating pouches of different thicknesses and different brands. Here at Mybinding.com, we recommend that you always use a carrier with your pouch laminators. It preserves the life of your investment. And with Mybinding brand pouches, we always include a carrier. The throat opening and therefore max width on this machine is 13” wide, great for all standard pouches. Although it has variable ...

Welcome to Mybinding video. What you see before you is the Akiles ProLam Ultra X6 Pouch Laminator. This is a heavy duty great workhorse of a machine. This pouch laminator will work with all kinds of laminating pouches of different thicknesses and different brands. Here at Mybinding.com, we recommend that you always use a carrier with your pouch laminators. It preserves the life of your investment. And with Mybinding brand pouches, we always include a carrier. The throat opening and therefore max width on this machine is 13” wide, great for all standard pouches. Although it has variable speeds, the X6 can run up to 59” per minute and it can handle a pouch thickness from 3 all the way up to 14 mil. It has 6 separate rollers, 4 for hot, and 2 for cold. A great machine that can handle both hot and cold lamination increases its versatility and saves you money in the long run. The ProLam Ultra X6 has a great LCD panel. It’s all touch screen and some of the features are hot and cold lamination, programmable memory, 9 different speeds, a backlit LCD, and push button temperature control. It’s pretty much jam free as it’s an easy machine to use but should you have a jam, there’s a reverse button right here on the front of the panel. You compress it, back out your project, and start again. A nice feature is the built-in permanent guide right on the machine itself. Print it right there on the middle so no need to use your manual around. Built to meet all kinds of laminating heeds, the ProLam X6 is a great investment. For more demos, reviews, and how-to’s, check out Mybinding.com.

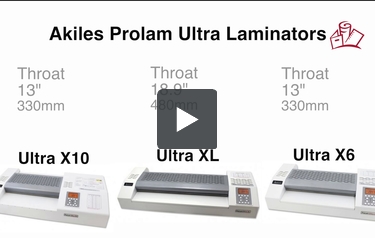

Akiles Comparing The Different Prolam Ultras Overview

Transcript :

Welcome to MyBinding video. This is a quick video comparing the different ProLam Ultras by Achilles. Let's take a look at the Ultra X10, the XL, and the X6. Of primary concern are the number of rollers. The X10 has 10 rollers, 6 Hot, 4 Cold, and the XL and X6 both have 6 rollers, 4 for Hot and 2 for Cold. In terms of throat opening, therefore the size of pouch you can use, the X10 and X6 both have a 13" throat. The XL has an 18.9" wide throat. The number of rollers and size of motor equals speed. The X10 can blaze at 142" per minute, the XL travels up to 47" per minute, and the X6, 59" ...

Welcome to MyBinding video. This is a quick video comparing the different ProLam Ultras by Achilles. Let's take a look at the Ultra X10, the XL, and the X6. Of primary concern are the number of rollers. The X10 has 10 rollers, 6 Hot, 4 Cold, and the XL and X6 both have 6 rollers, 4 for Hot and 2 for Cold. In terms of throat opening, therefore the size of pouch you can use, the X10 and X6 both have a 13" throat. The XL has an 18.9" wide throat. The number of rollers and size of motor equals speed. The X10 can blaze at 142" per minute, the XL travels up to 47" per minute, and the X6, 59" per minute. And finally, when it comes to pouch thickness, all three machines have a max pouch thickness of 14 mil or 350 microns. All three are excellent hot and cold laminating machines will serve you well. Give us a call if you have any questions. For more demos, reviews, and how-to's, check out MyBinding.com.

Compare to Similar Pouch Laminators

Questions & Answers

Thank you for your question. The rollers are made of silicon, it is not necessary but still recommended to use a pouch carrier with this laminator.

Answered by MyBinding

▶

Asked by Fran Meehan

Thank you for your question. Although thermal laminating pouches have adhesive that is activated by the lamination process the glue stick better to itself than to the paper. You can trim it down but if it is trimmed down to the edge of the page it does break the seal around the edge and there is the potential for it to peal. This is a situation i would recommend making a sample testing how well the adhesive will stick to the stock you are using.

Answered by MyBinding

Thank you for your question. If you are getting cloudy results generally speaking it is because the laminate isn't getting hot enough for long enough. Both options are potential fixes, but there is not a specific resolution for all situations. I would first lower the speed and if you are still seeing cloudy results gradually increase the temperature. Running it at too hot of a temperature can cause the laminate to melt too much so be sure raise the temperature in steps and test each step to find the ideal temperature for your specific project.

Answered by MyBinding